Task

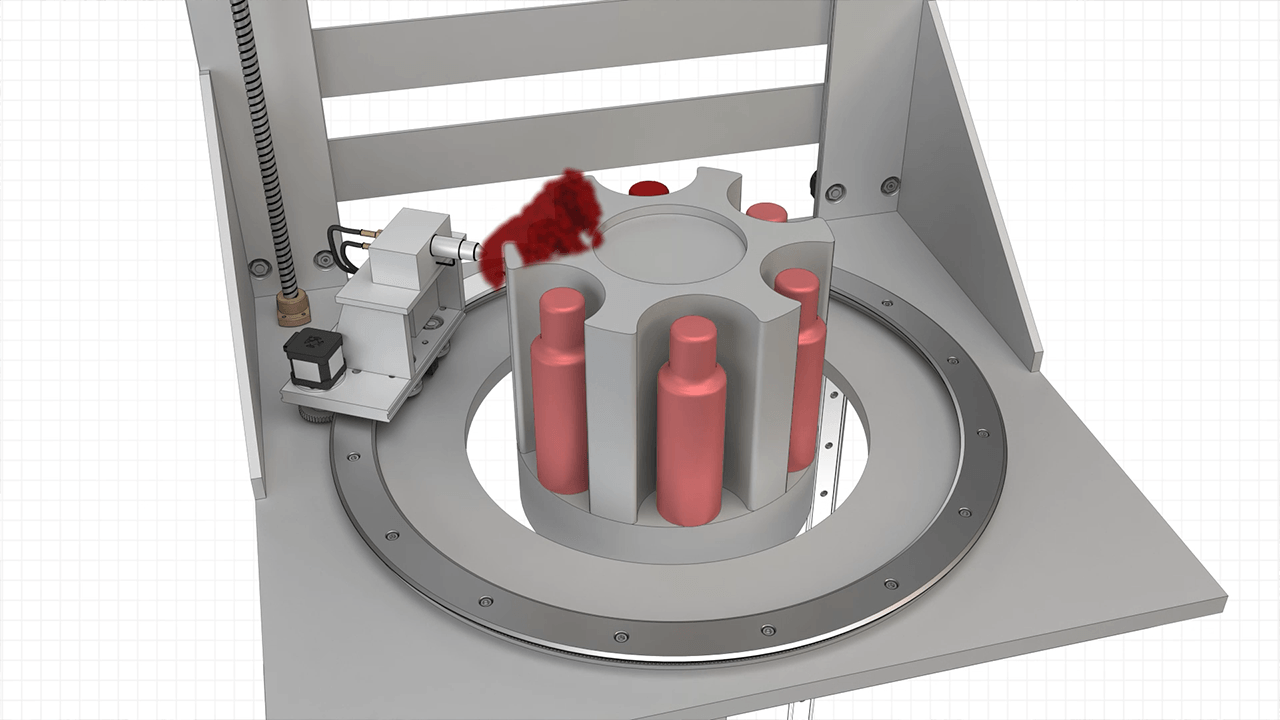

This Spanish producer of cosmetics was facing a life problem with an existing wheel based system that uses shaft fitted into aluminium rails. After 3000km, travel accuracy was being lost due to play developing in the system.

This required a considerable amount of down time and replacement before the machine was running again. Fitted to the guidance system is a large overhanging flat plate that carries the perfume mixing unit that has to stop at various stations over 4.3m to receive the fragrances for mixing. With a 100kg axial load and an offset torque of 250Nm a quality steel based system was needed to improve life and accuracy.

Solution

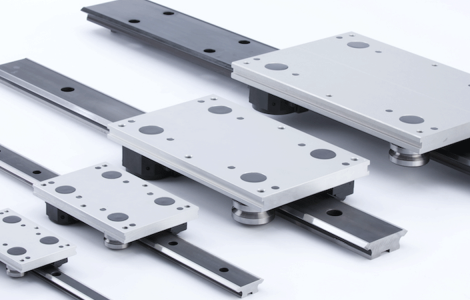

The first issue was to address the offset load and use one linear rail that would be wide enough to withstand the forces involved. Within GV3 there is a wide range of steel guide rails and a 120mm width rail was selected. To provide the rigidity and life required size 54 double row bearings fitted to the moving carriage were used along with a rack fitted directly to the rail to provide the drive.

Scope of Supply

1 x NL120P3R L5000 linear rail plus rack driven carriage AURD12054 L510DRCS

Result

The NL120 linear rail is more suitable to applications where high offset loads are required although there was always the possibility of fitting two rails in parallel. However, with the extra setting involved it was preferable to avoid this if one rail could suffice. Incorporating the rack fitted to the linear guide made it easier to provide the drive system without the need to set separate components. The use of solid steel linear rails provided greater rigidity with the benefit from the positive bearing line contact that GV3 V rails offer resulting in a longer system life.

Recommended for you

Contact us

Tel Sales Enquiries +44 (0)1884 257000 General Enquiries +44 (0)1884 243400

Email [email protected]

Address

HepcoMotion Head Office

Lower Moor Business Park

Tiverton Way

Tiverton

Devon, EX16 6TG

Contact Form