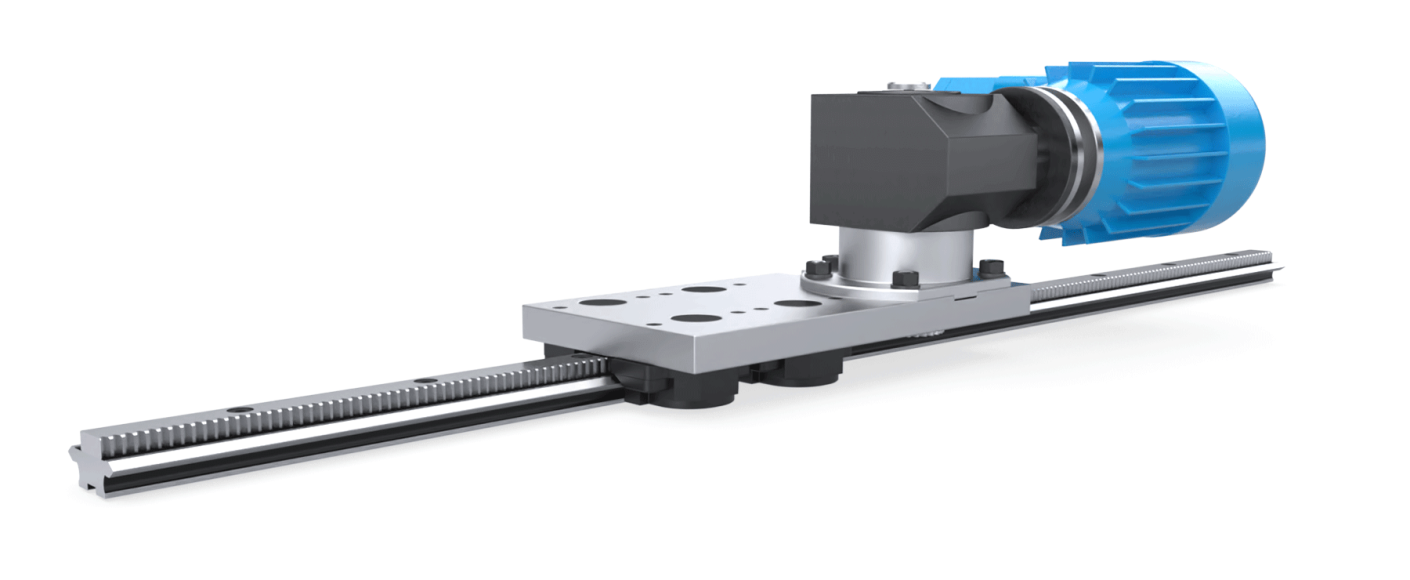

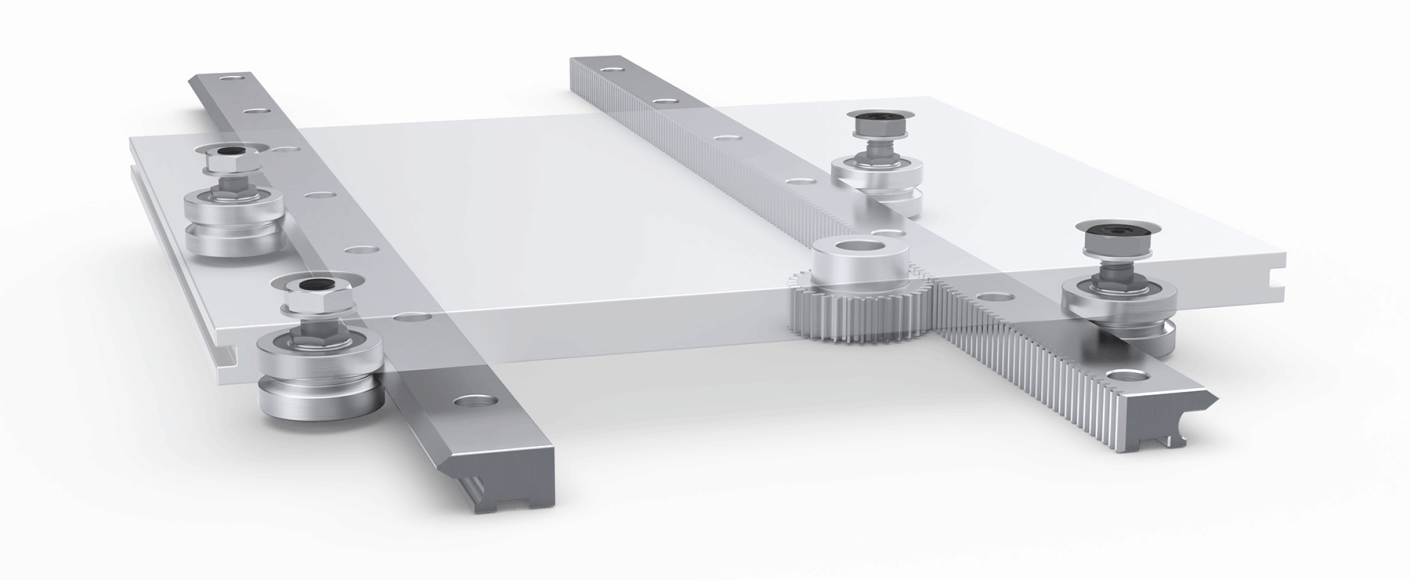

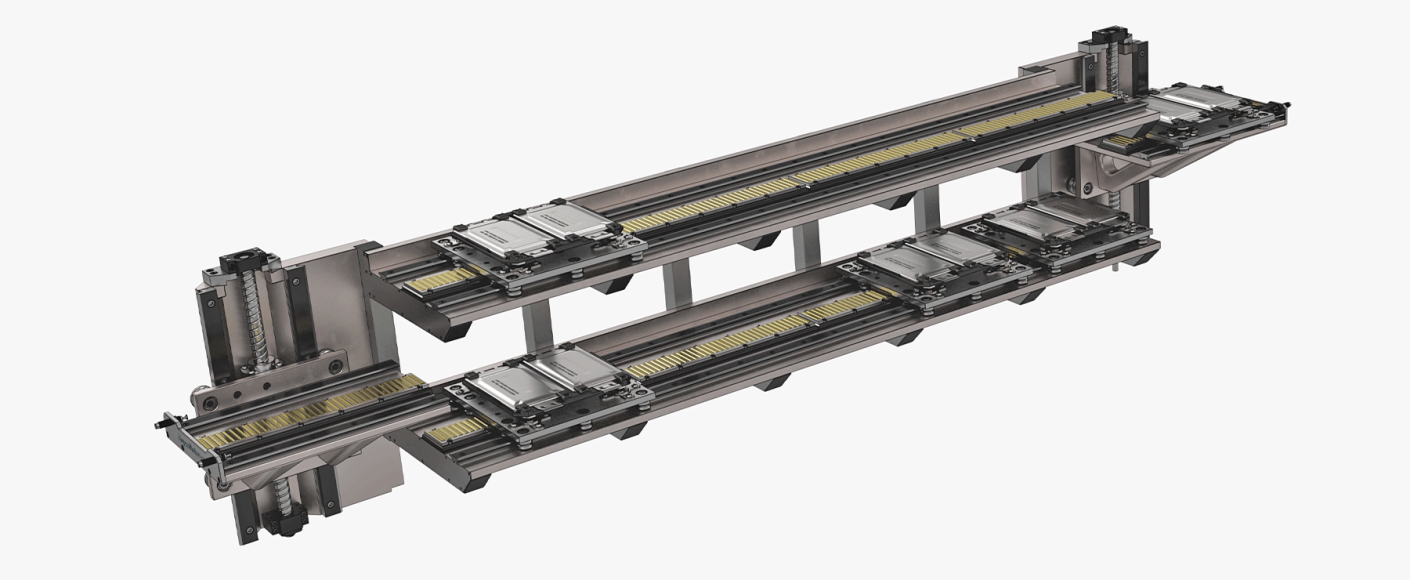

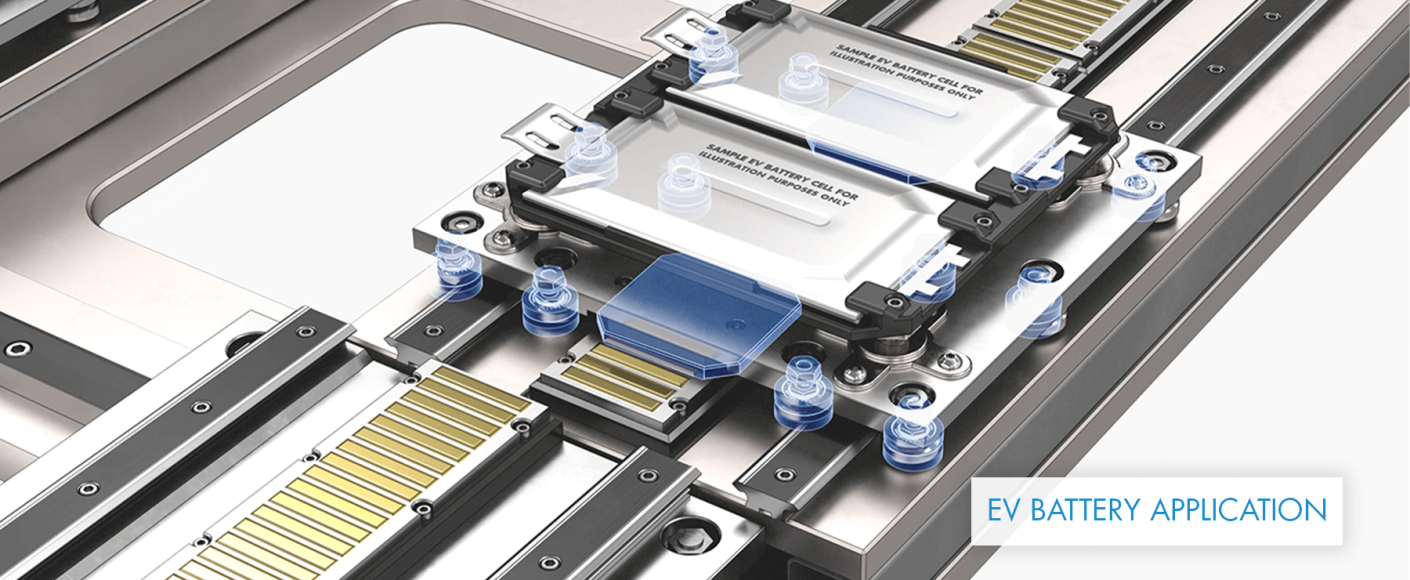

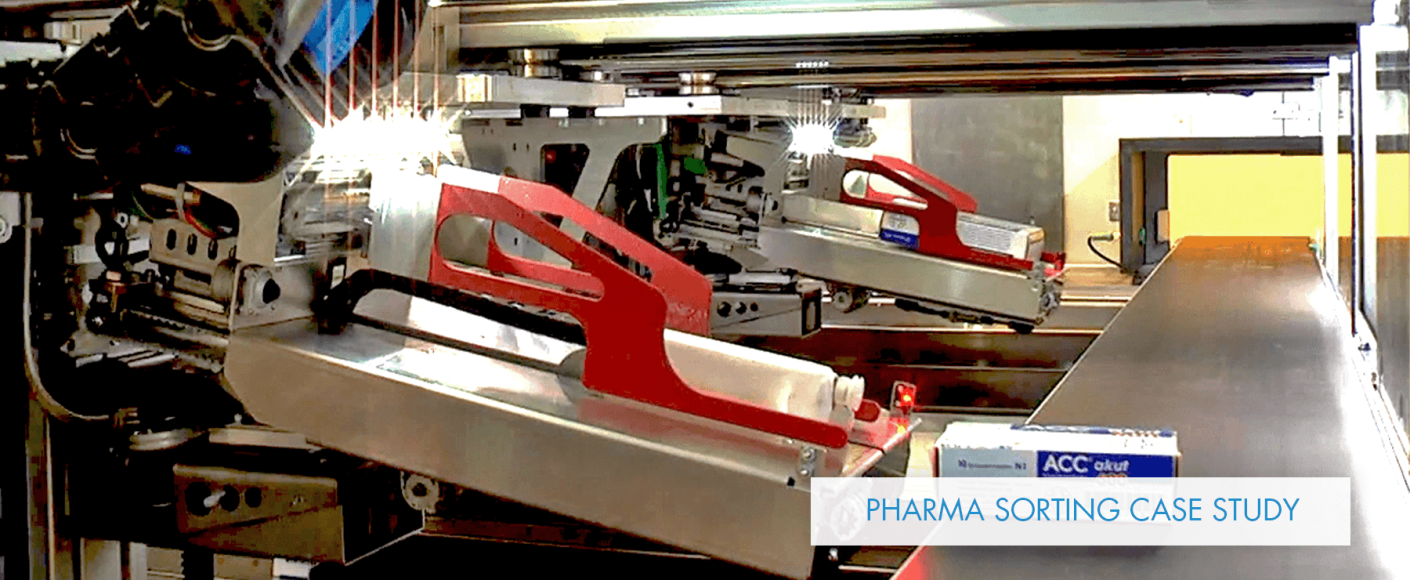

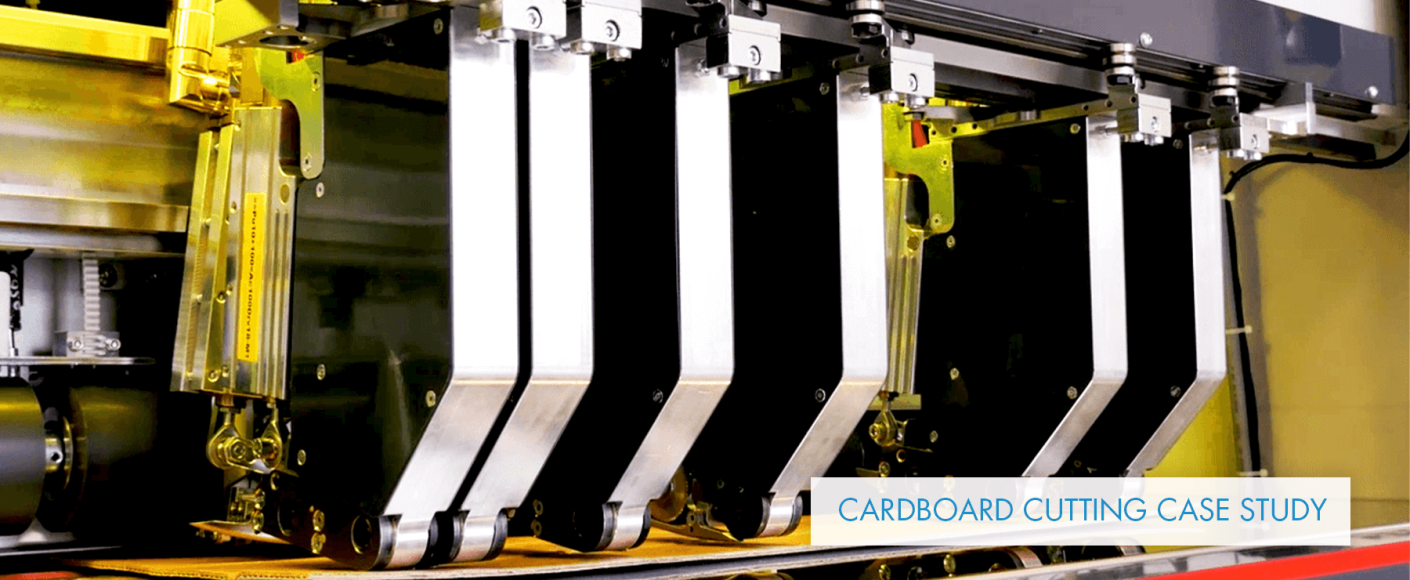

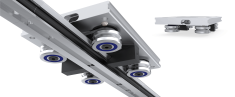

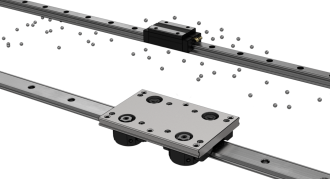

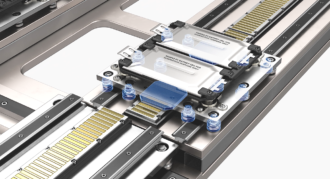

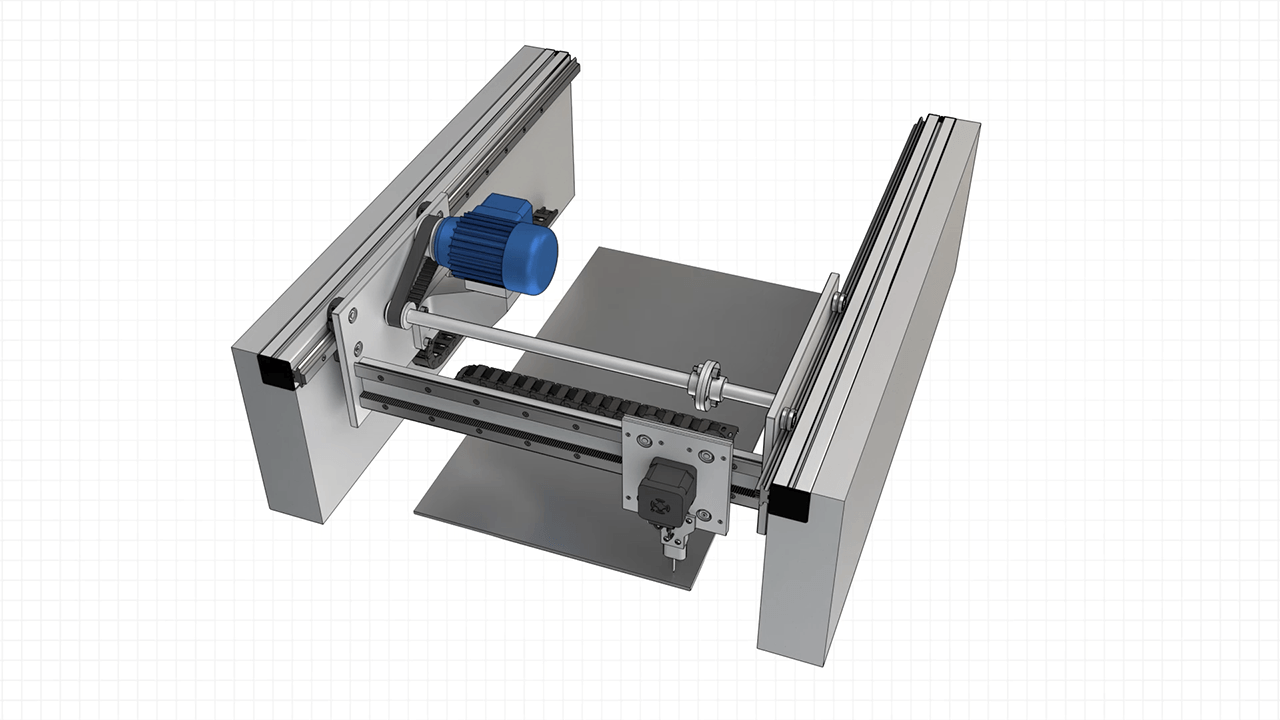

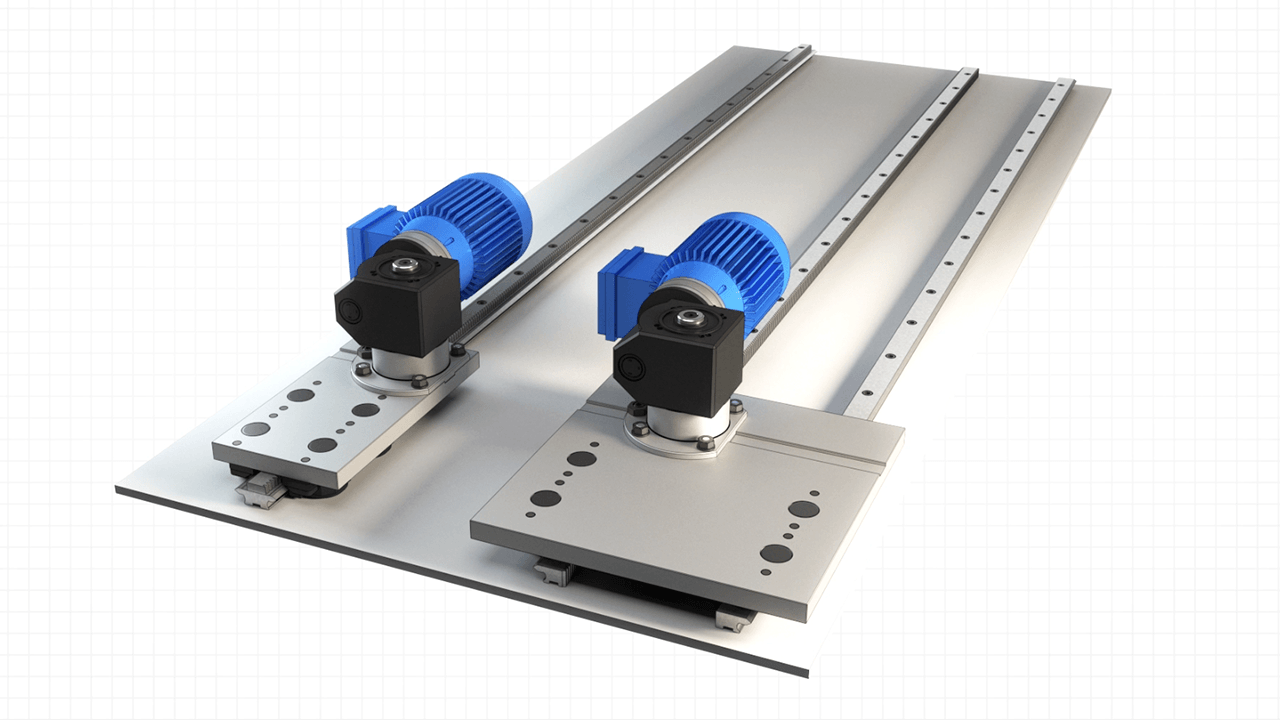

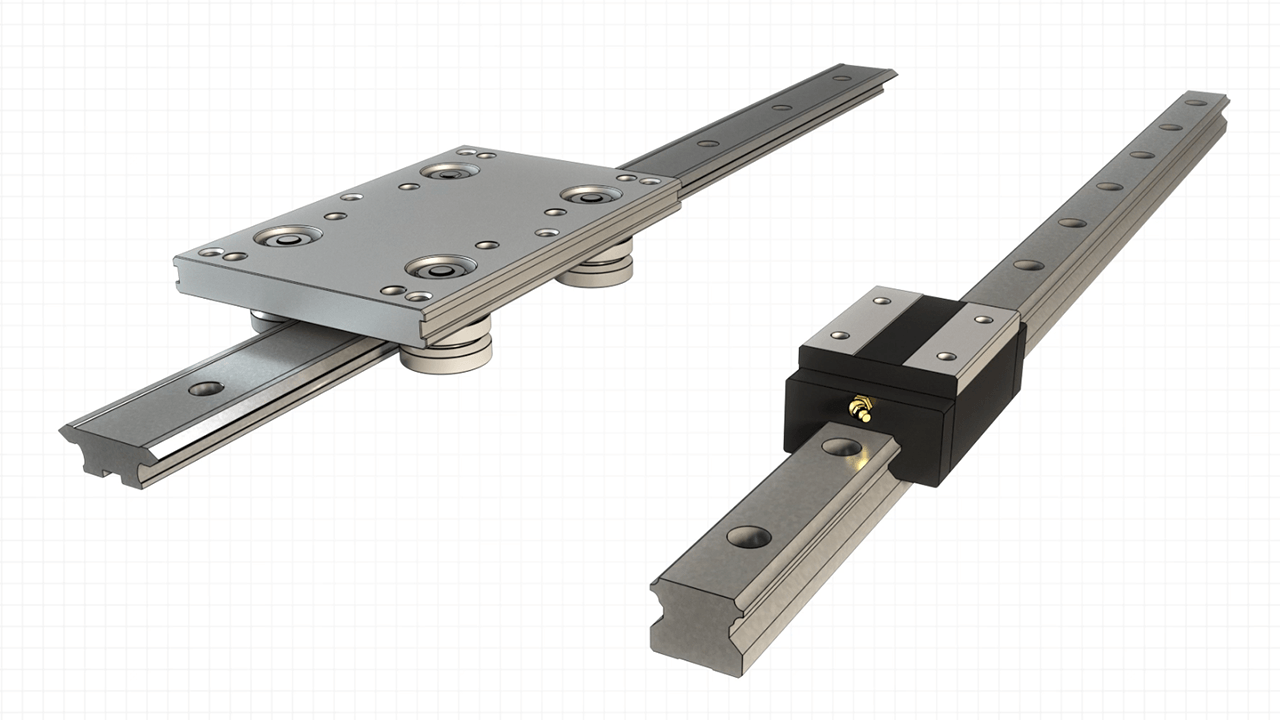

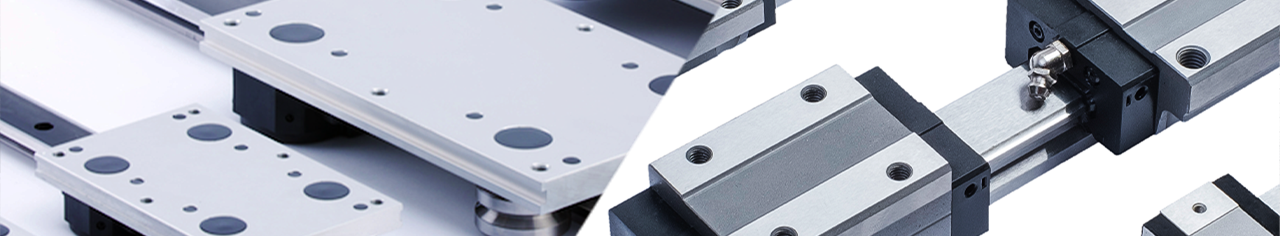

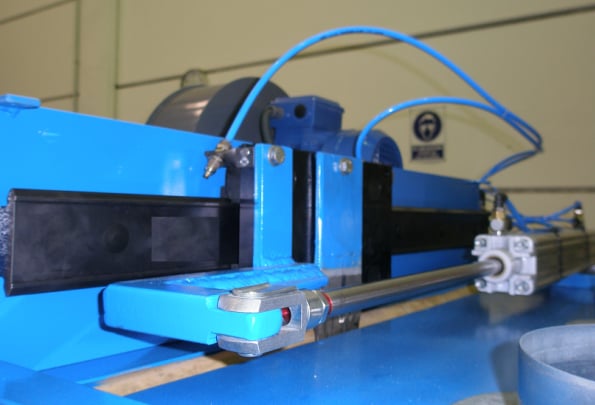

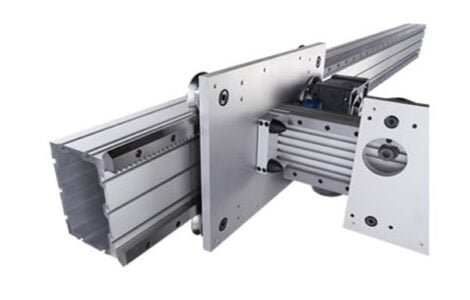

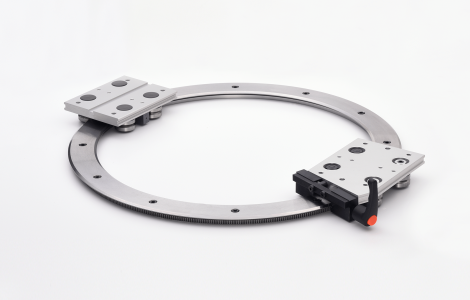

An extremely versatile, reliable and hardwearing linear motion system, designed to serve a diverse range of automation and linear applications.

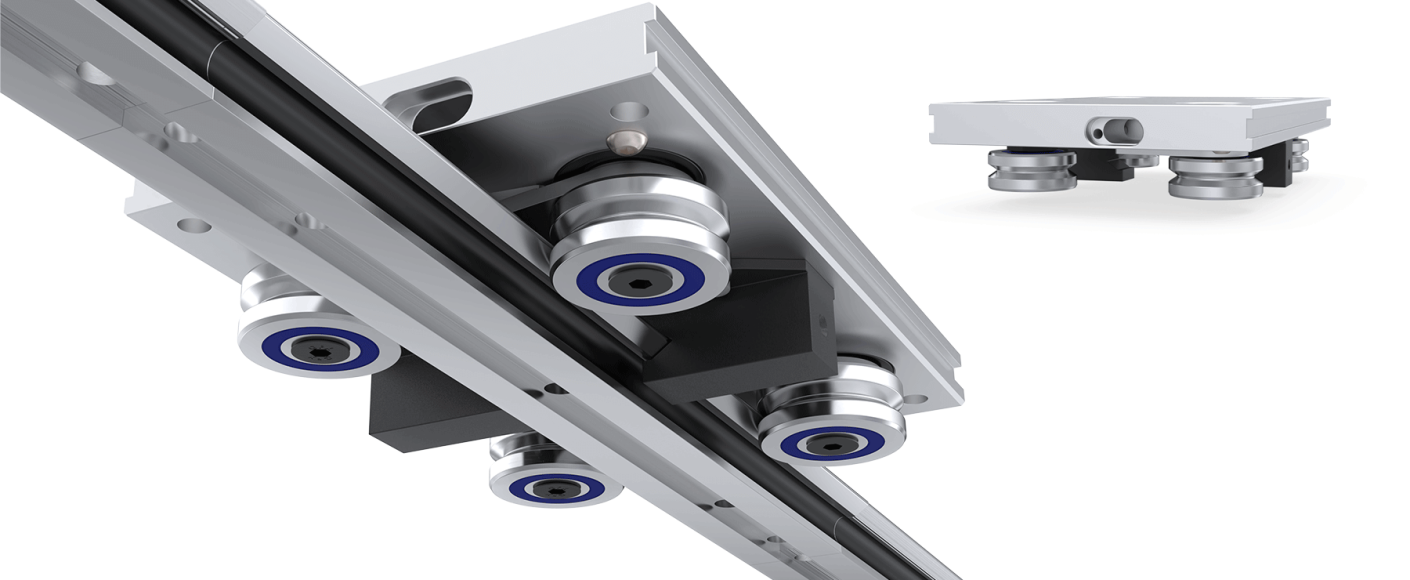

Smooth, fast and reliable – Featuring V guide technology, GV3 offers a long system life, low maintenance and increased productivity, saving time and money.

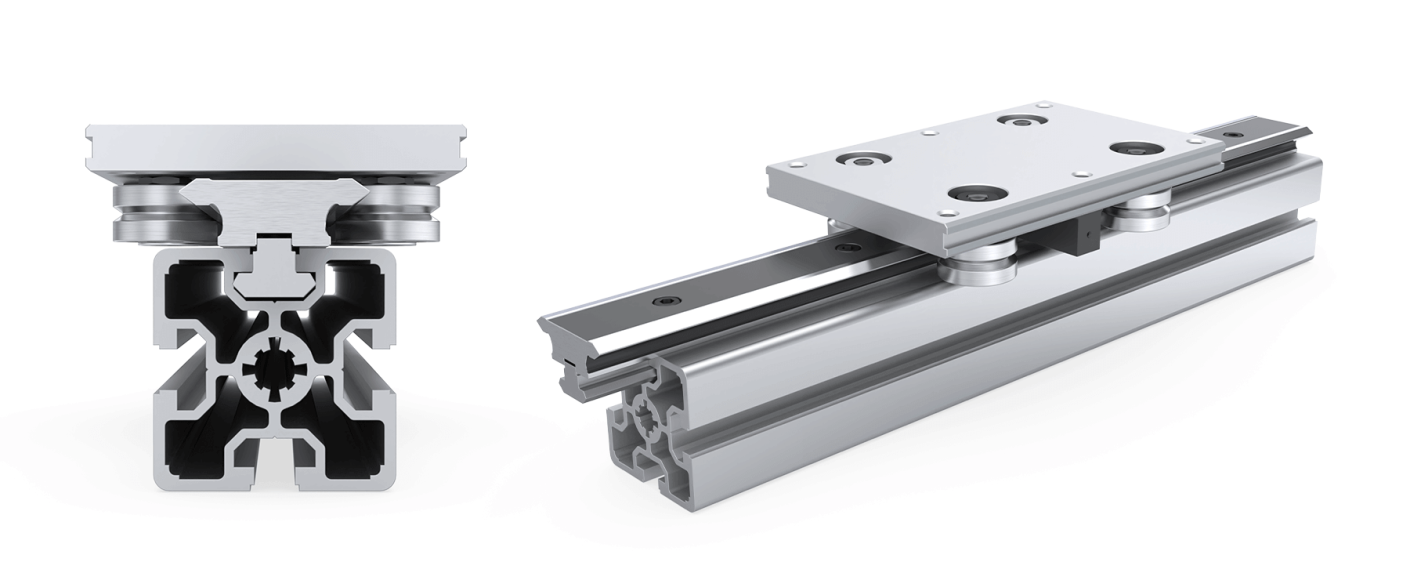

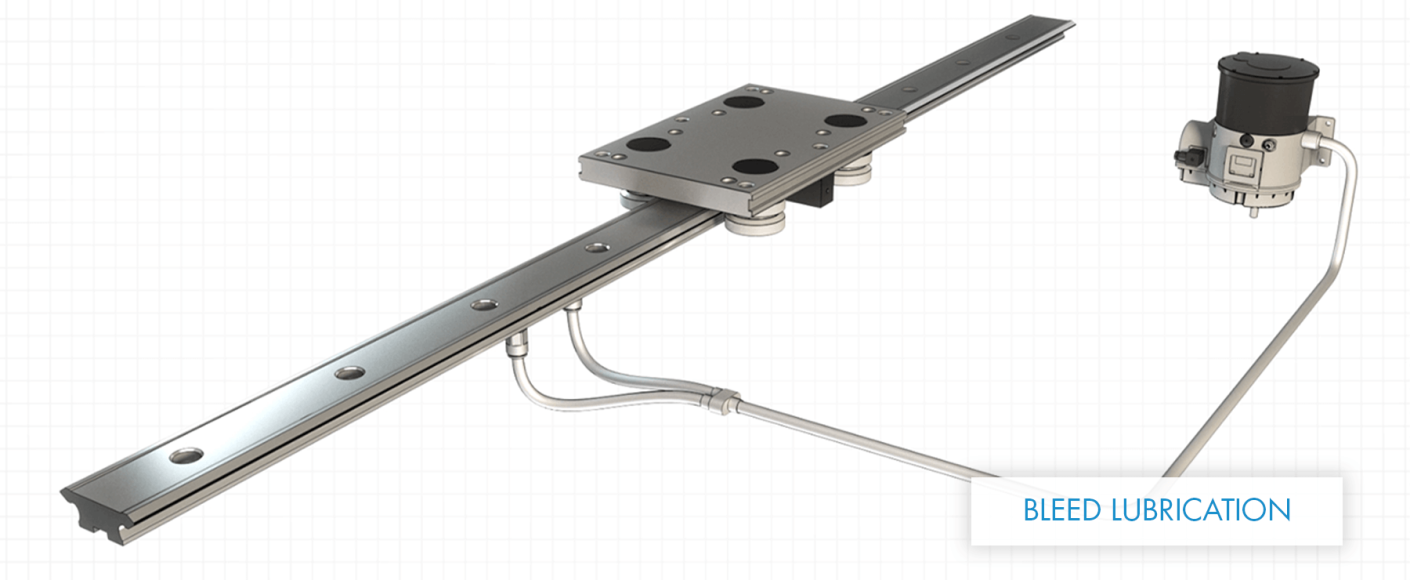

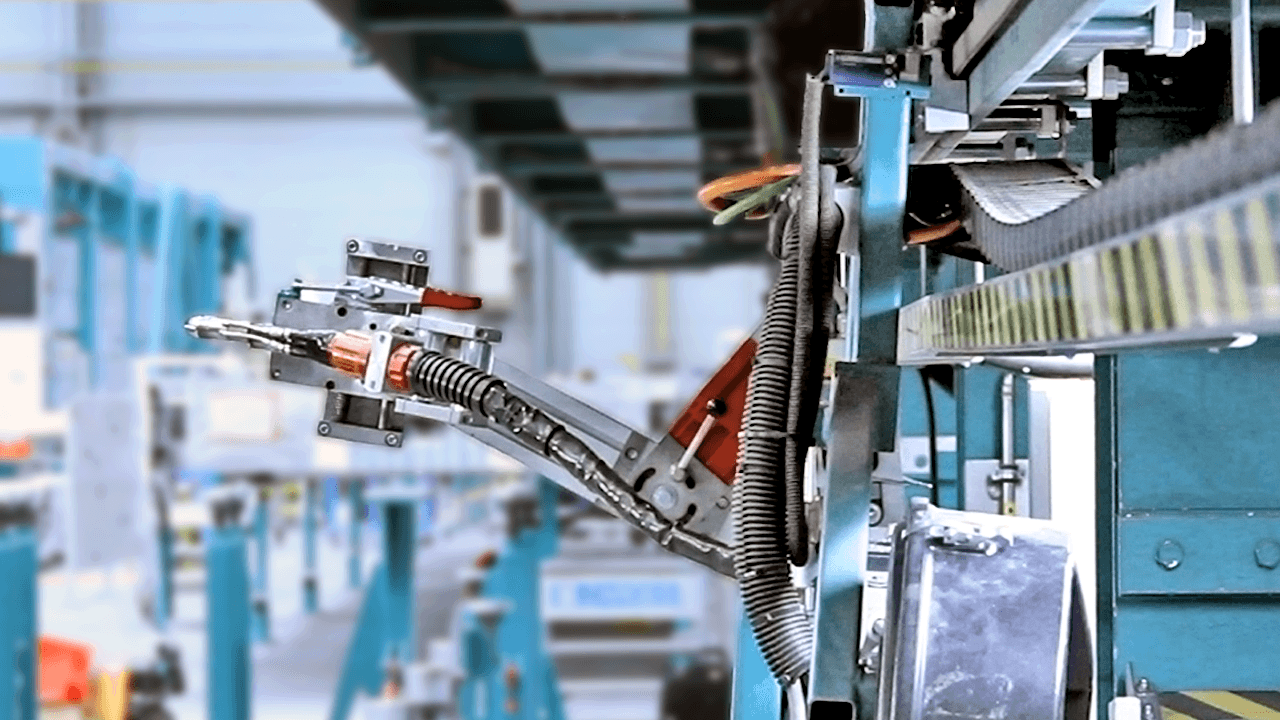

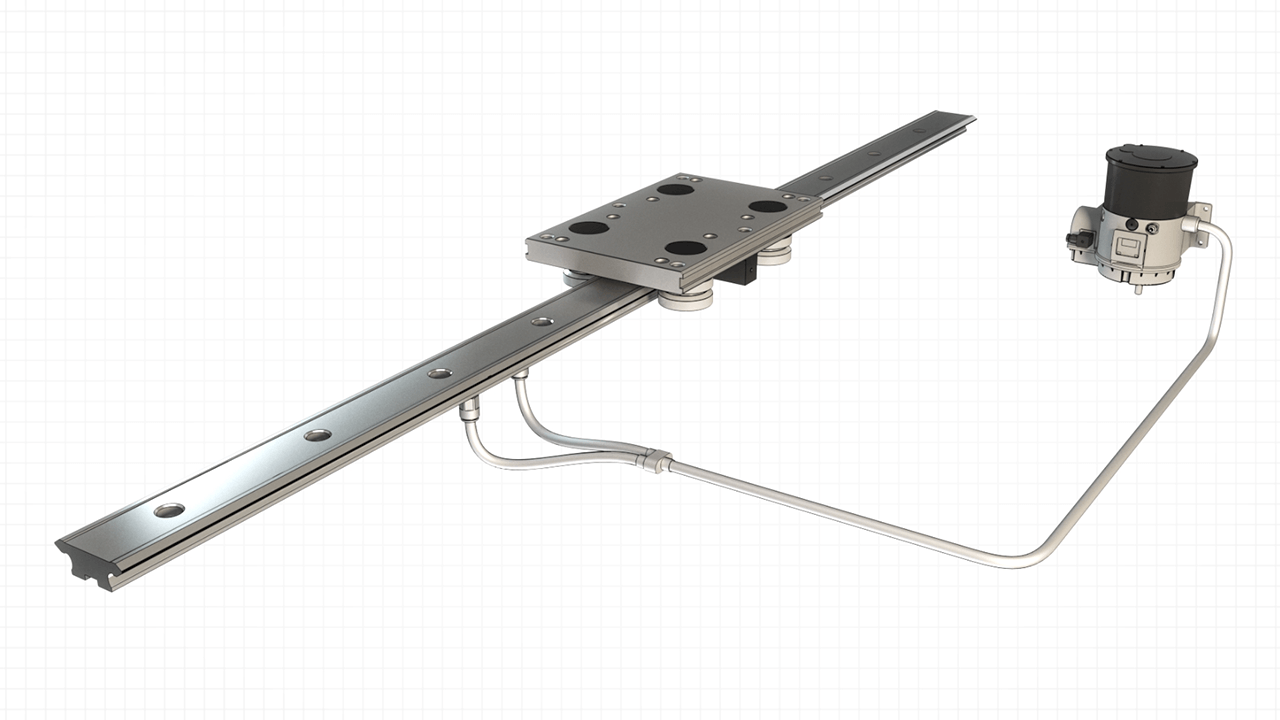

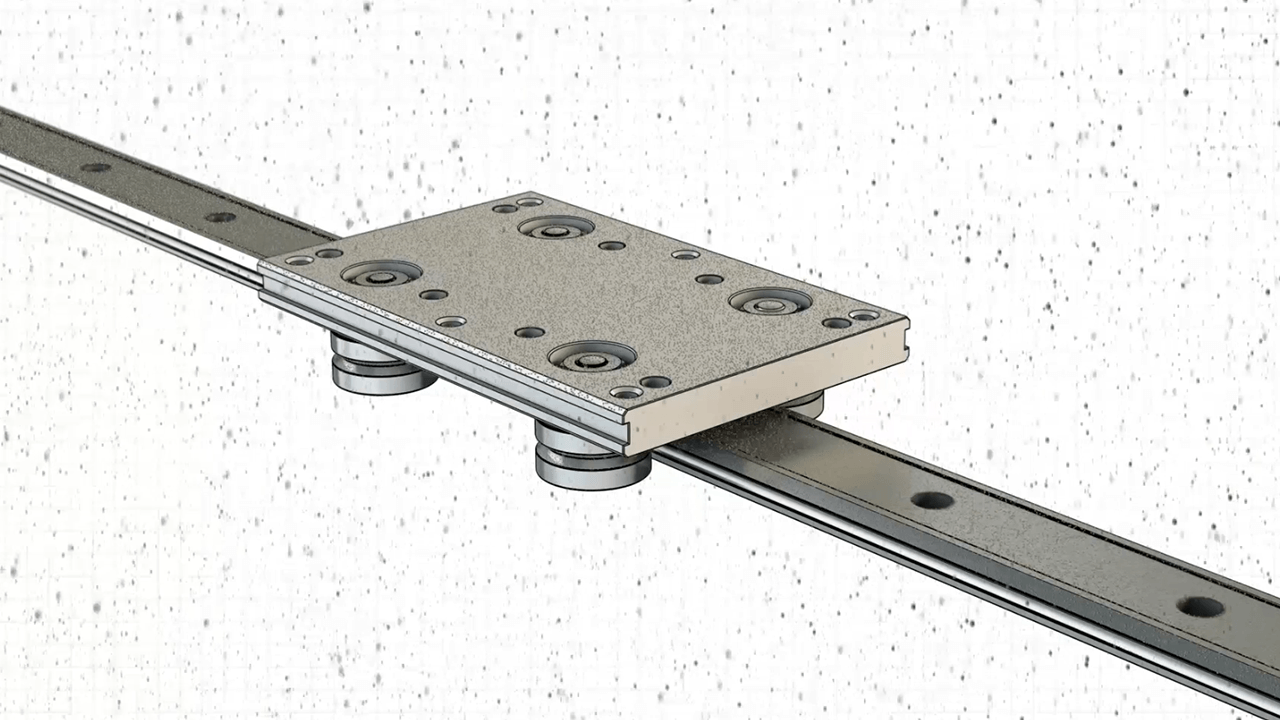

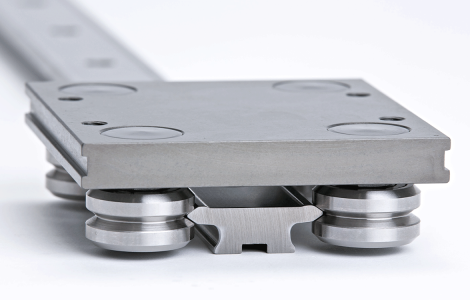

A fit-and-forget solution – High quality material, hardened V edges and bearings internally lubricated for life ensures the system requires very little maintenance.

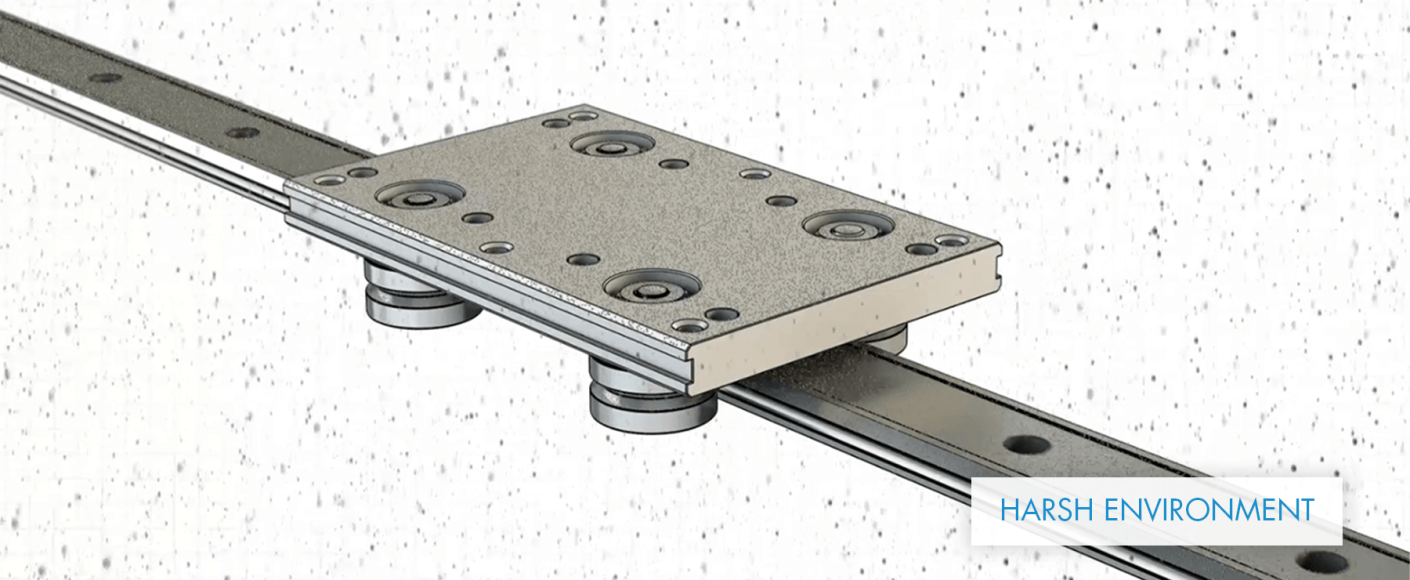

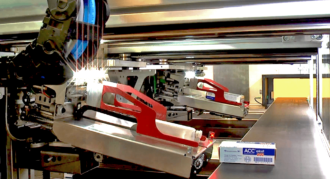

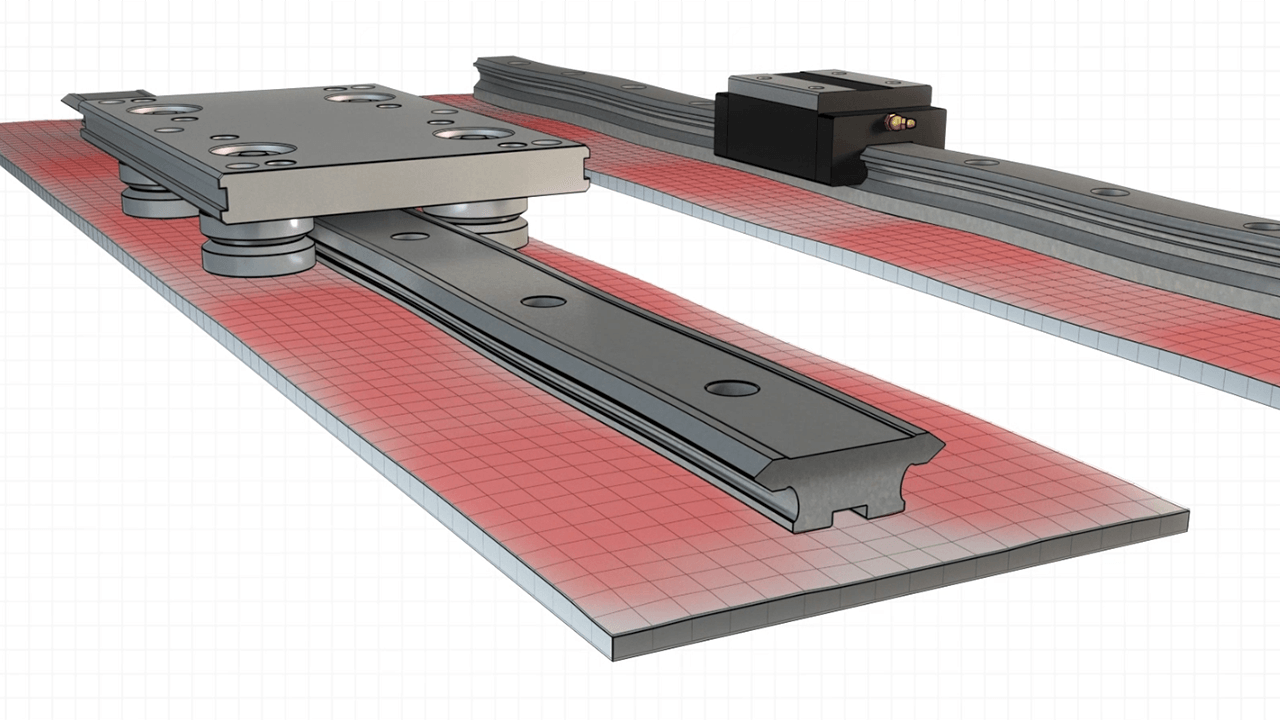

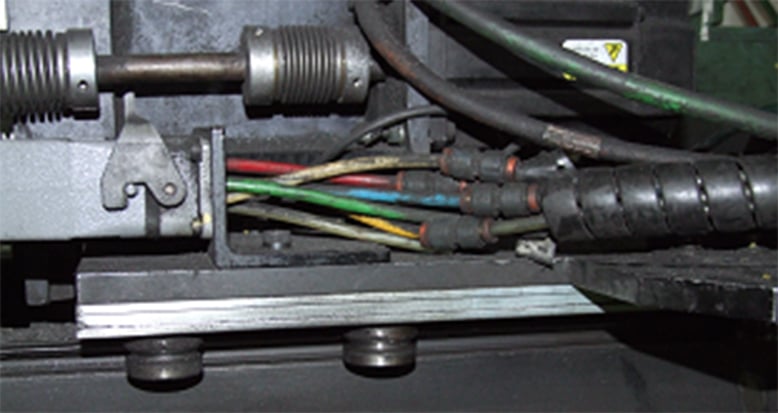

Suitable for challenging environments – A unique wiping action expels debris, keeping machines running and reliable.

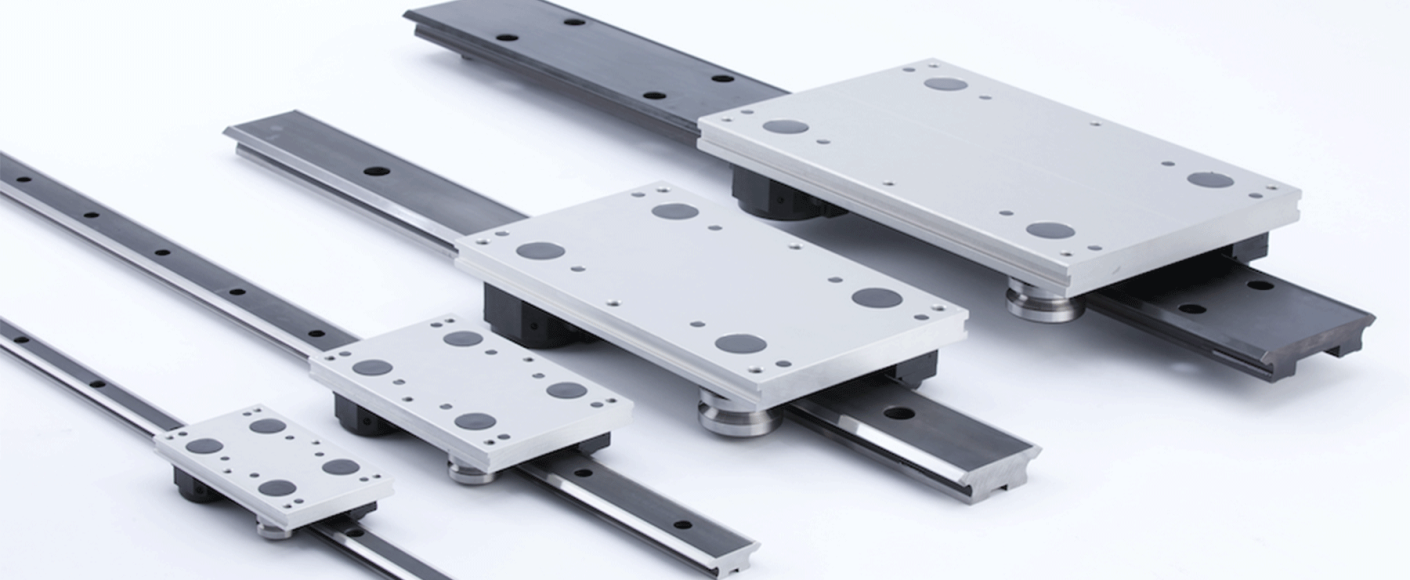

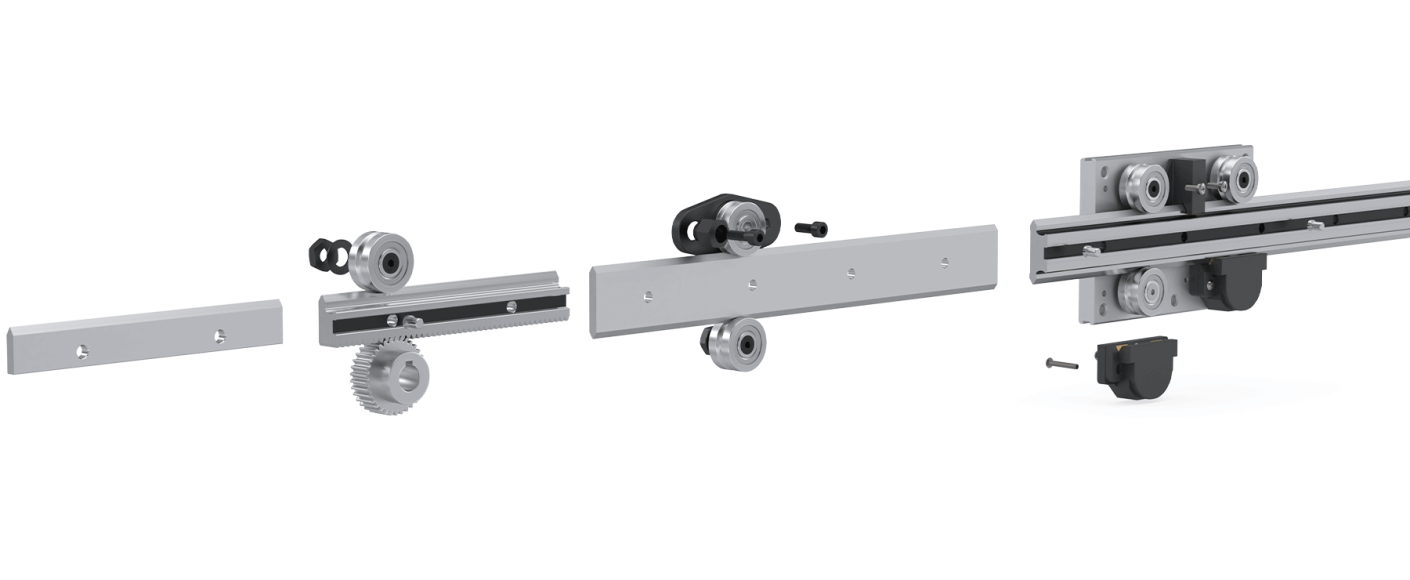

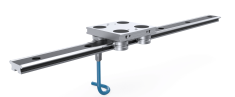

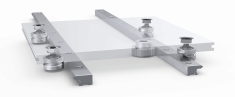

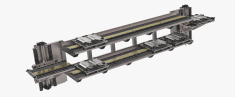

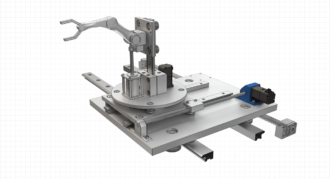

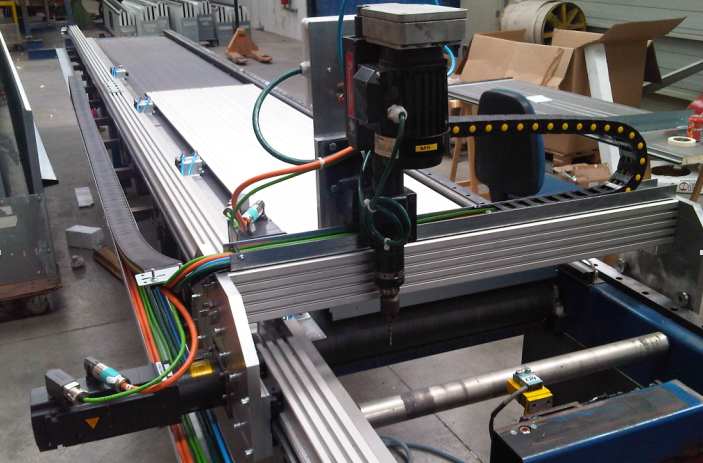

Choice and flexibility – GV3 is available as an assembled unit or as individual components.

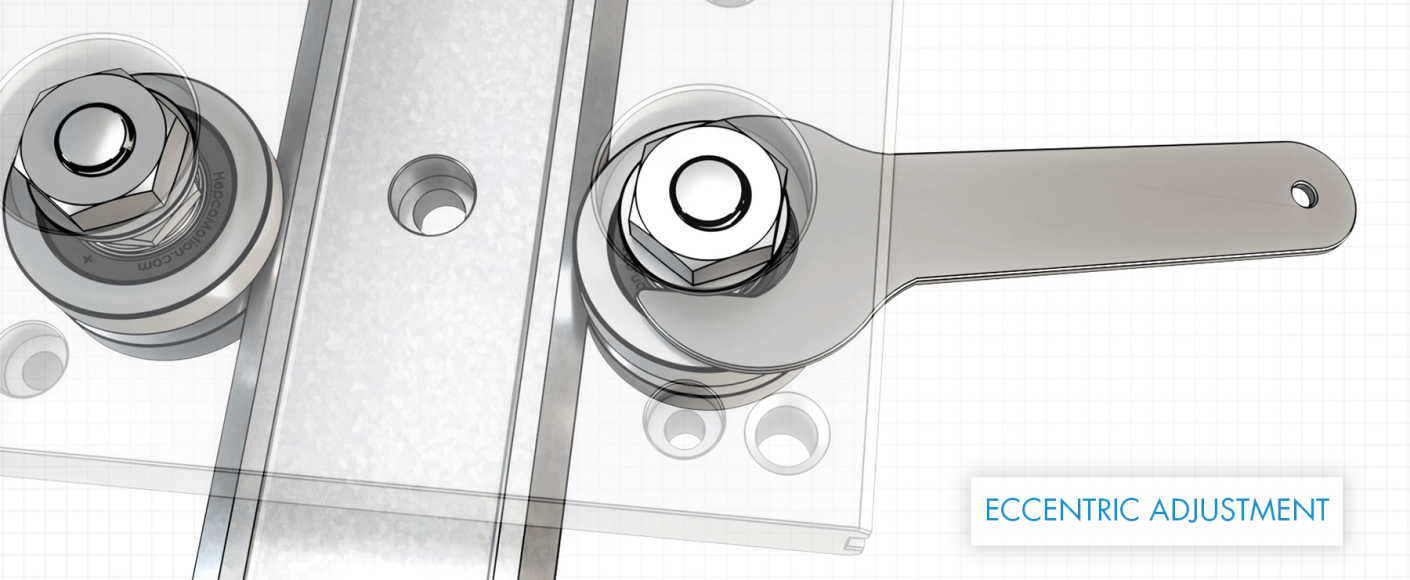

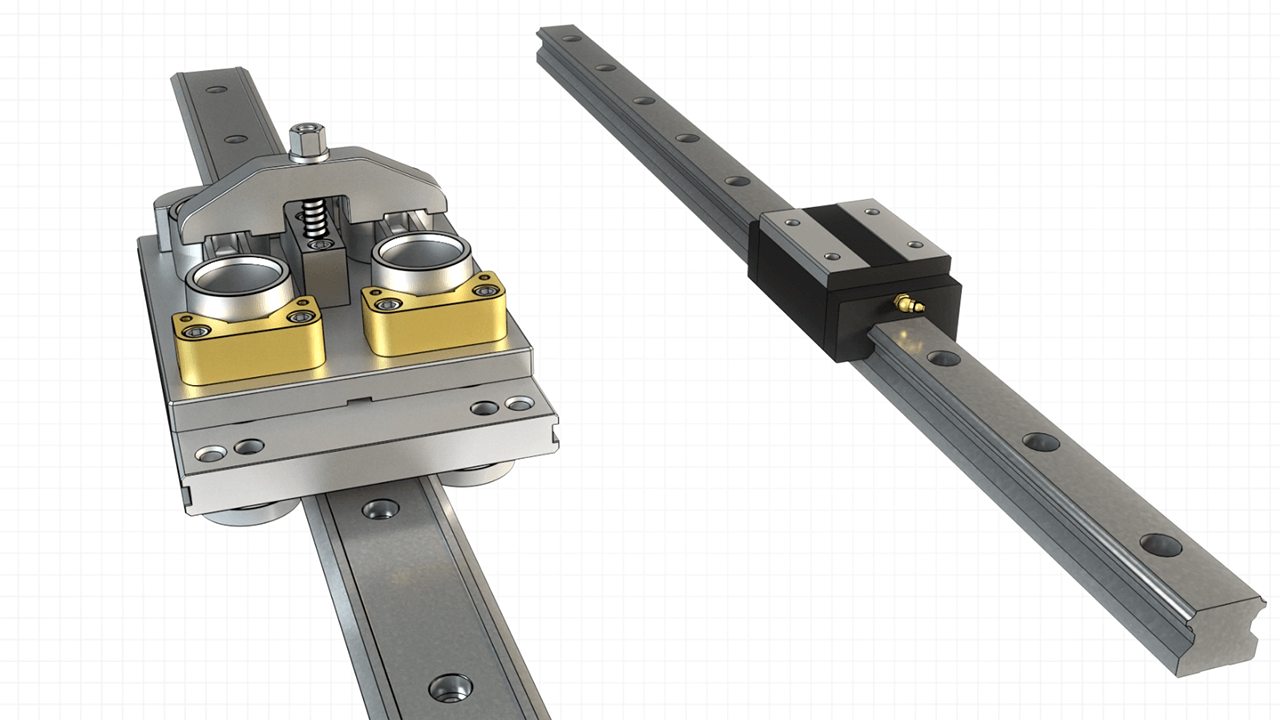

Adjust don’t replace – Linear bearings can be adjusted instead of being replaced, reducing maintenance costs.

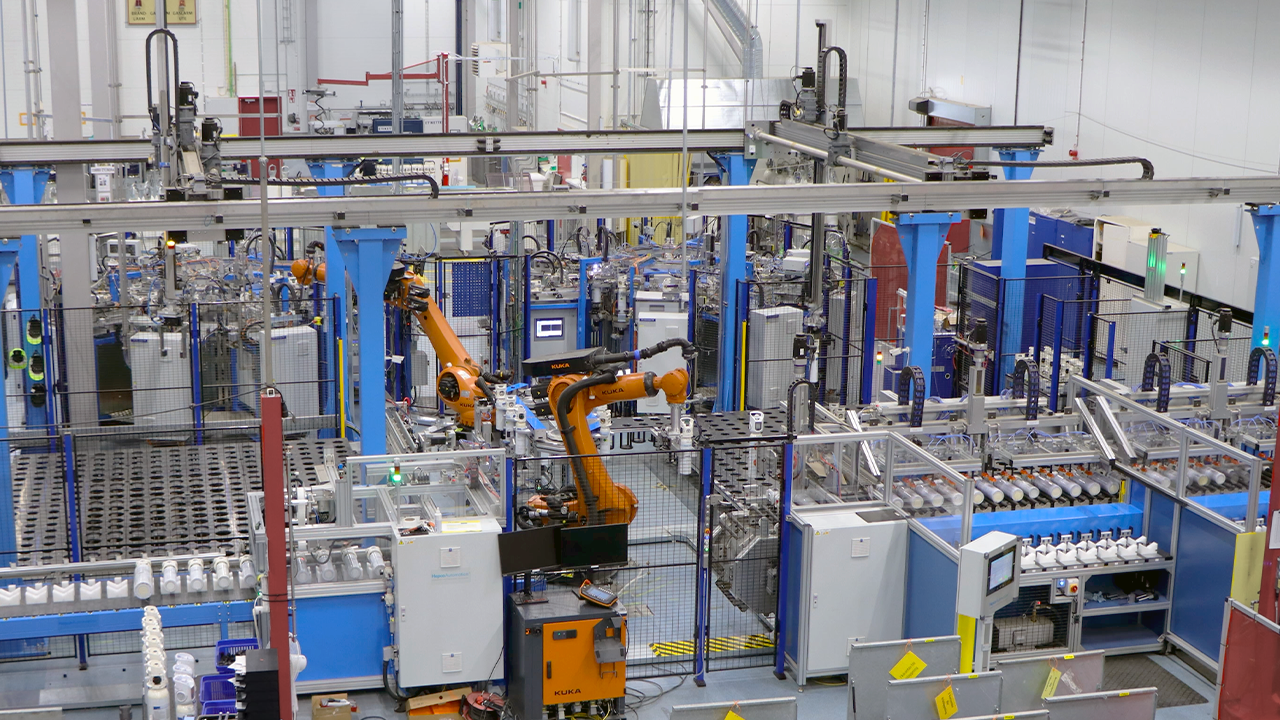

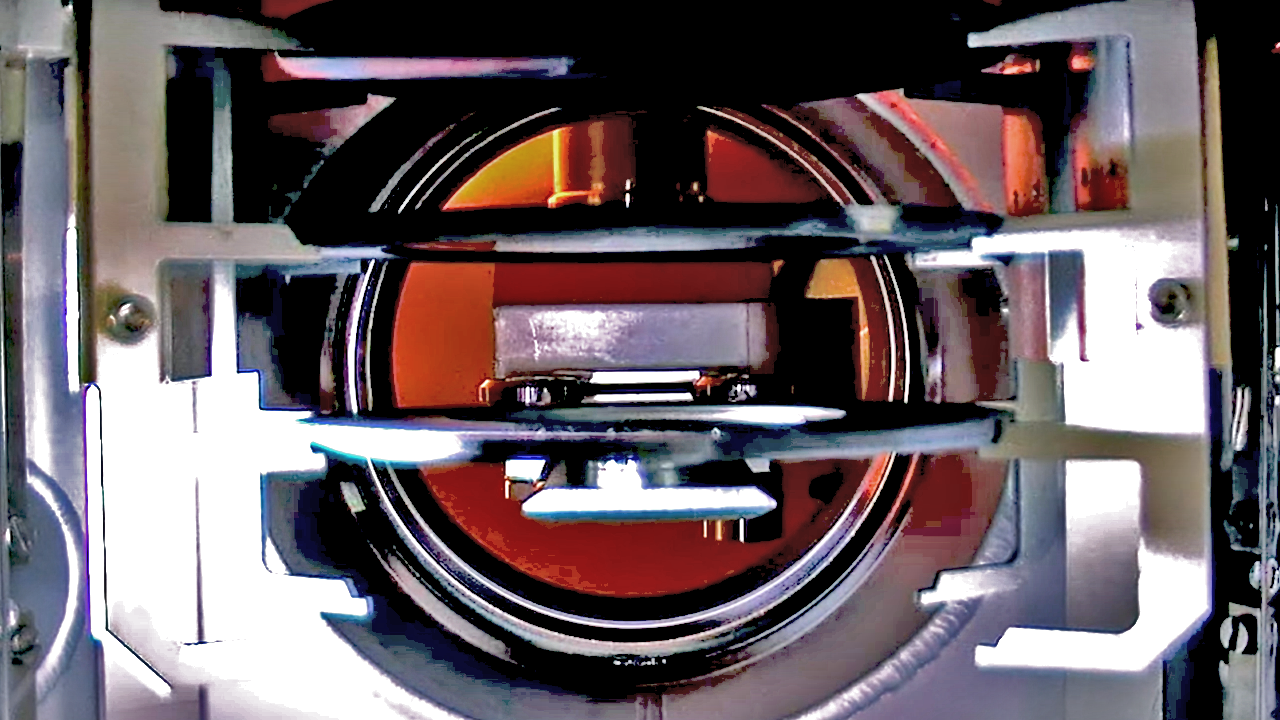

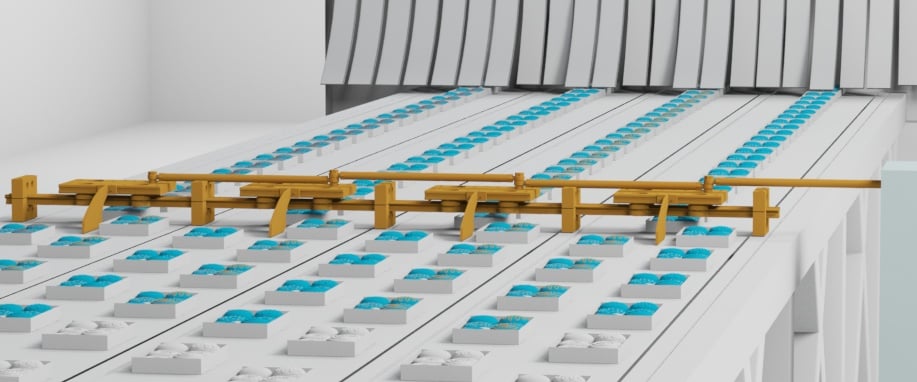

- GV3 is one of the quietest and fastest linear systems available, offering speeds up to 10 m/s, allowing a higher throughput

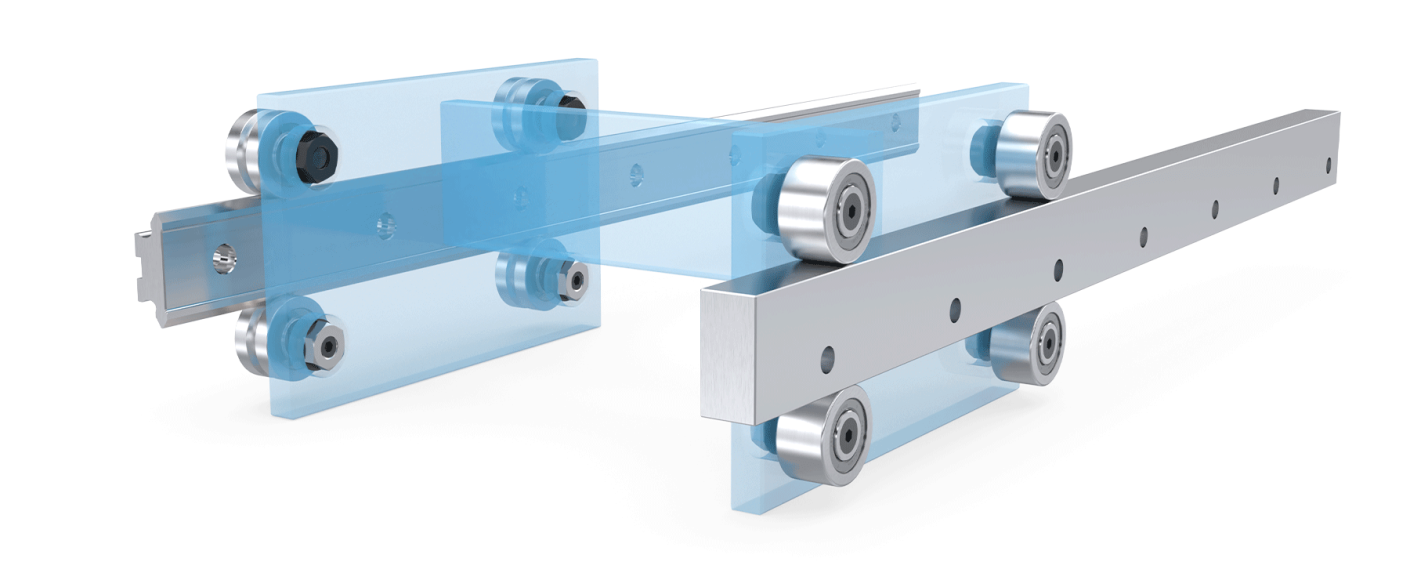

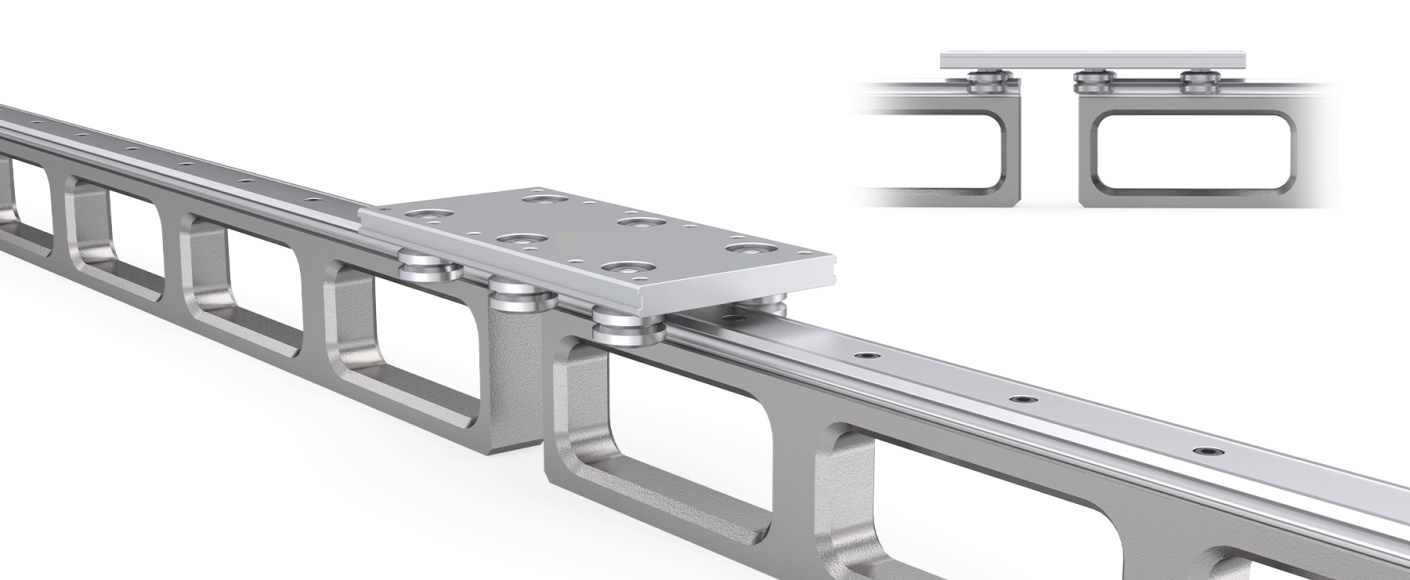

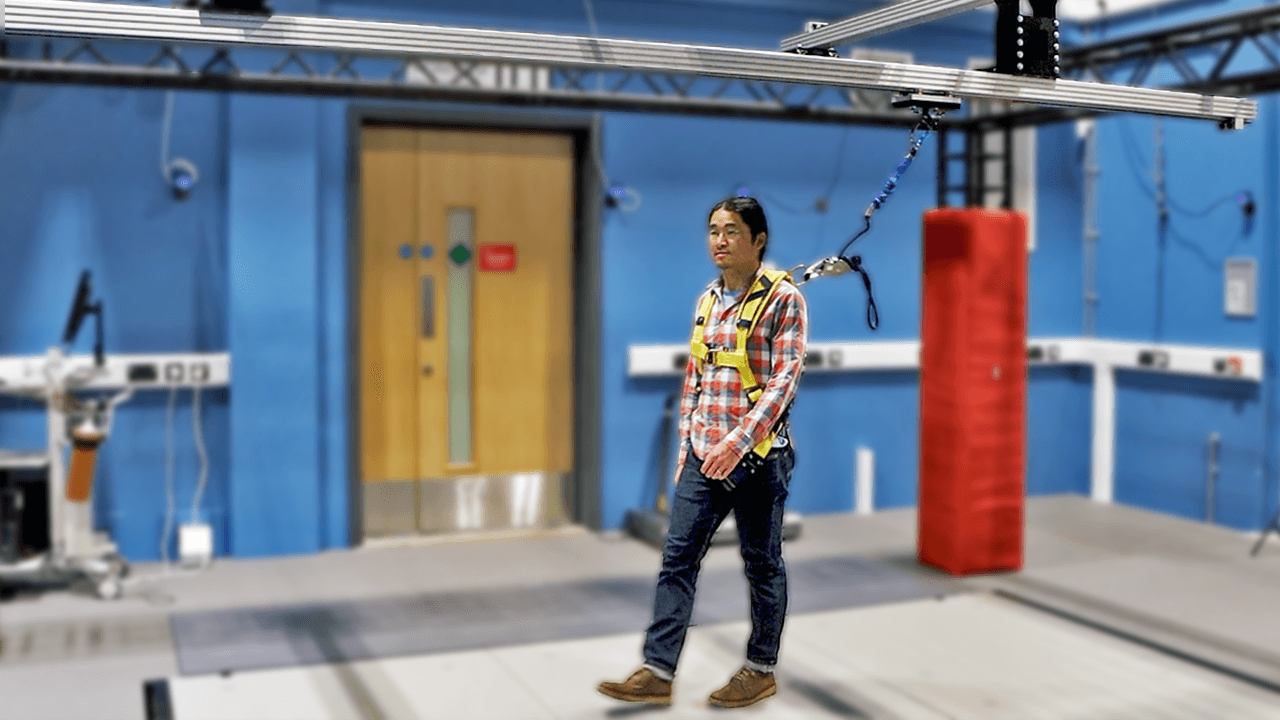

- GV3 can operate in any plane or orientation, allowing unrestricted use in machine construction

- Loads can be applied from the top, bottom or each side of the carriage radially or axially

- GV3 can operate without lubrication if required

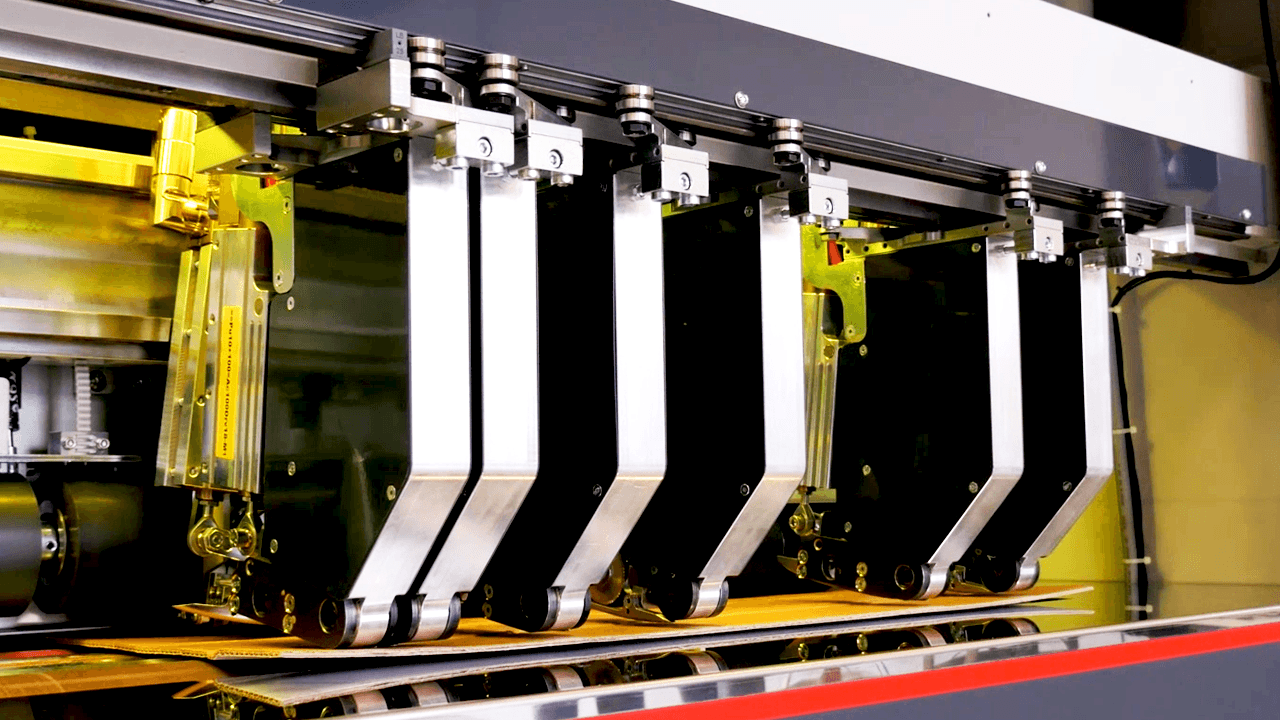

- There are 12 standard slide sizes on offer with single or double edge options, and flat slide or slides incorporating a spacer for simplified installation

- Slides are available in three different precision grades, allowing systems to be specified for optimum performance with the budget available

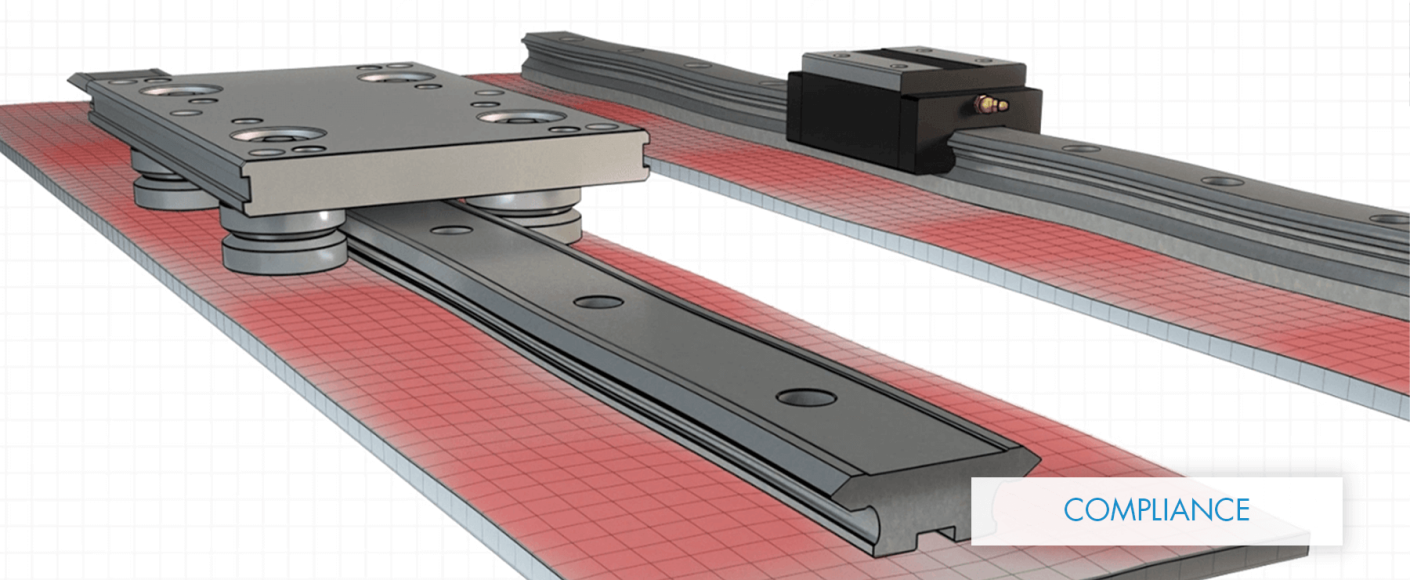

- Twin bearings offer a degree of compliance for easier installation and smooth running while the double row option maximises radial and axial capacity

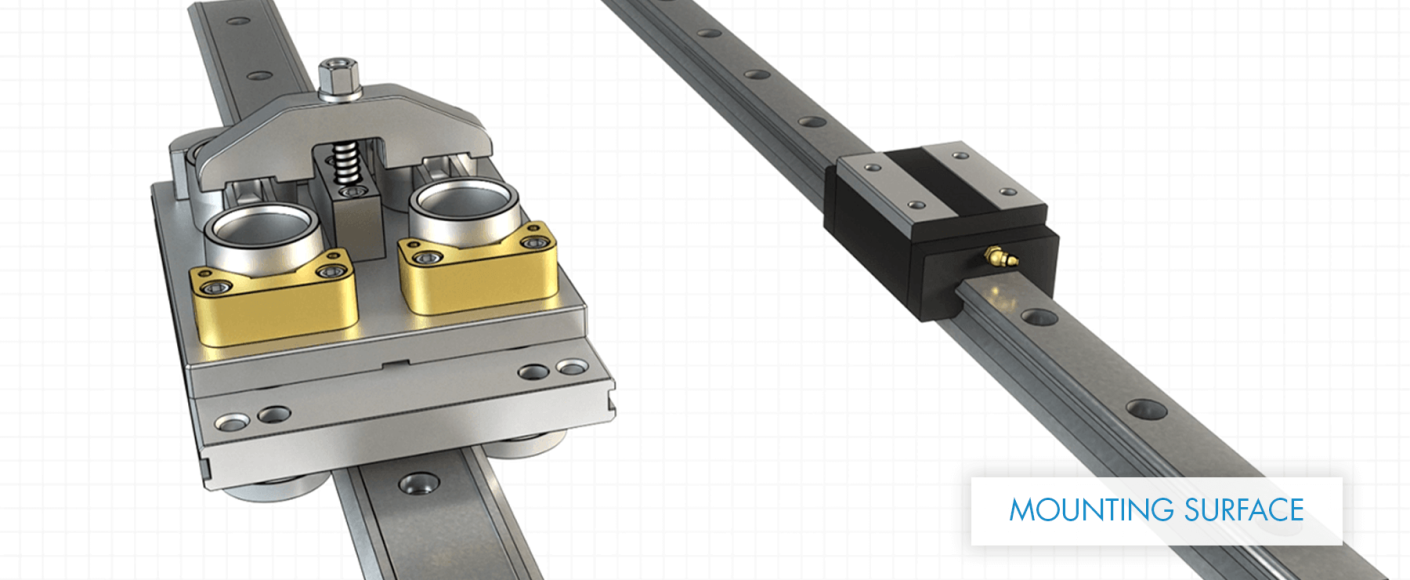

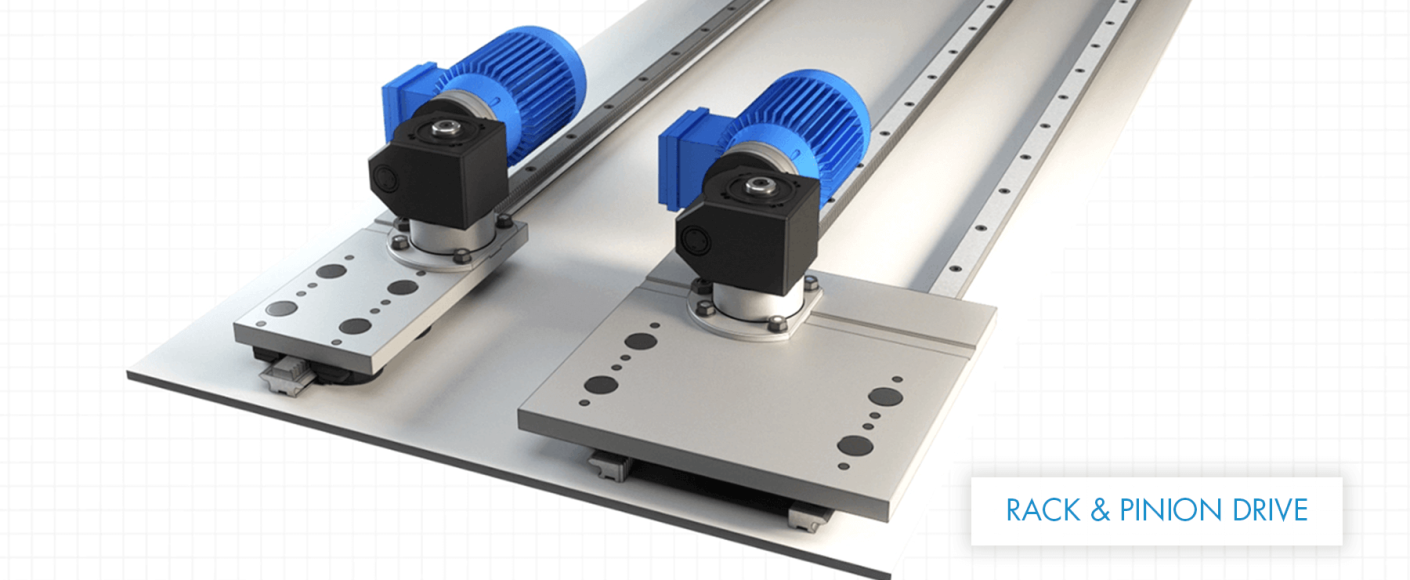

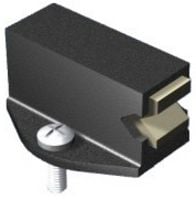

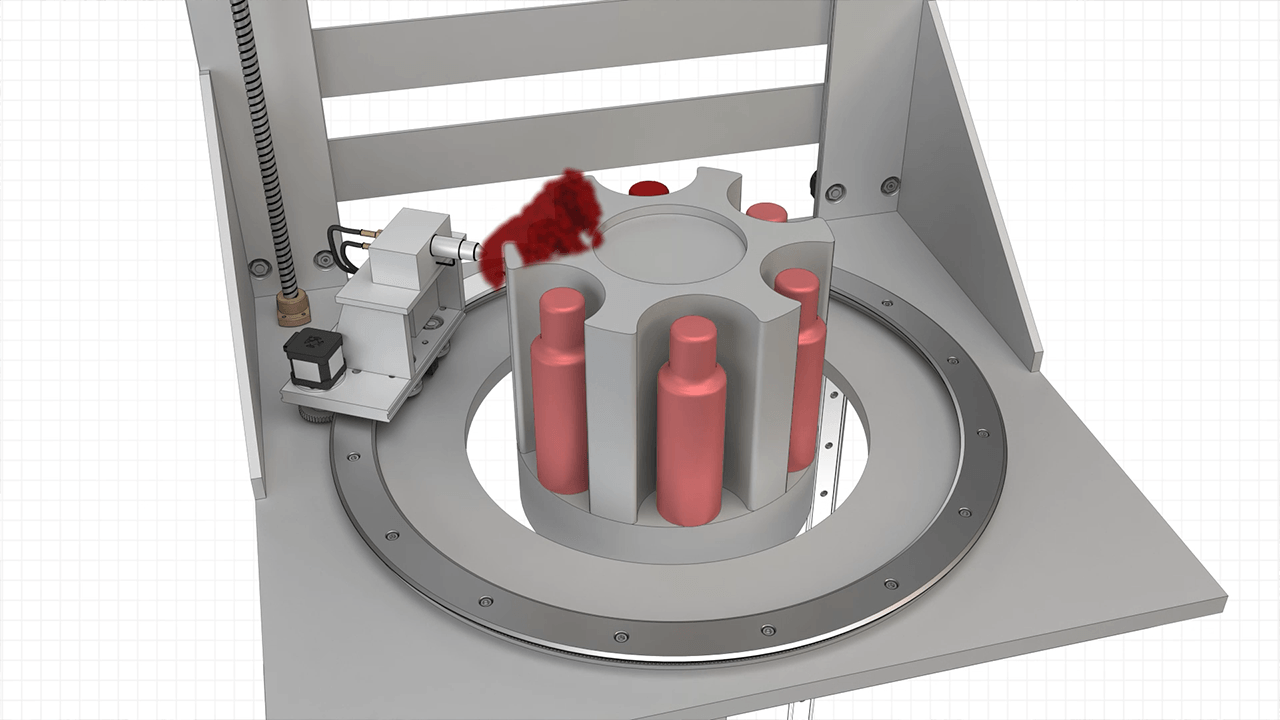

Product Components

Bearing sizes and their load capacity

This diagram provides an overview of the bearing sizes available and their load capacity depending on the application type.

Contact us

Tel Sales Enquiries +44 (0)1884 257000 General Enquiries +44 (0)1884 243400

Email [email protected]

Address

HepcoMotion Head Office

Lower Moor Business Park

Tiverton Way

Tiverton

Devon, EX16 6TG

Contact Form