There are many factors to consider when designing a production cell or system; one of these key decisions is which drive system to use. Independently controlled movers offer flexibility, freedom of choice and the ability to customise. On the other hand, mechanically linked carriages offer stability, security and durability.

Each decision has its consequences and it is important to carefully consider which option is better in the long term. Similarly, a design engineer may wonder which format best suits his production cell: linked or free moving? Specifically, it is a matter of choosing between linear motor driven systems and mechanically linked systems.

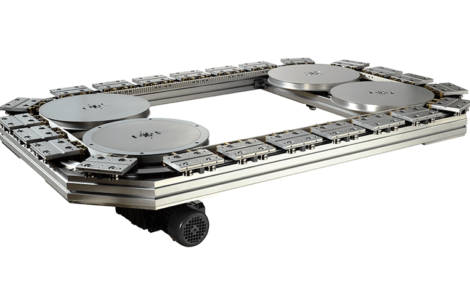

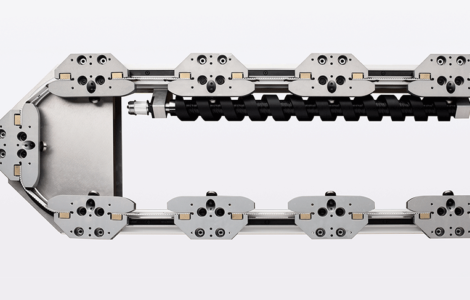

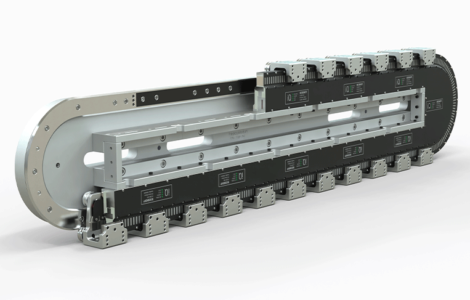

HepcoMotion has been producing and supplying high quality linear guide components and systems for over 50 years, and offers solutions for both methods of drive. High performance linked systems such as the Driven Track System (DTS) are one of its core products, and more recently HepcoMotion’s GFX guidance system for Beckhoff XTS, one of the leading linear drive manufacturers, is proving to be a much sought-after product. With product offerings for both drive systems, HepcoMotion often discusses with customers which solution is best for their needs.

Three advantages of linear motors

Systems driven using linear motors offer three benefits: flexibility, speed and precision. A common goal is to be faster, more flexible and often more precise, but whether the investment is worthwhile ultimately depends on whether these features are just ‘nice to have’ or actually deliver quantifiable advantages in a production cell. Before making a decision

on the type of system required, the following must be assessed: what should the new system aim to achieve – more precision, higher speed or more flexibility?

The main distinction between systems with linked carriages and those with independently controllable movers is, of course, flexibility. With linear motor systems, production is not limited by the slowest process. Processes with varying throughput times can be linked seamlessly. This optimisation significantly increases production efficiency and, where necessary, previously separate production processes can be integrated into a single cell. This can negate the need for multiple systems in a production cell, in turn reducing cell footprint.

Additionally, in a system with individually controllable movers, programming can easily be adapted to accommodate additional work steps or a change of product. This is an incredibly important feature in the ever changing production environment because there are constant changes in many areas of manufacturing. Comparatively, there is no such flexibility in a system with mechanically linked carriages.

Linear motor systems offer complete flexibility, in this application individual carriage movement is used to grip bottles for a sorting application, allowing a system output of 200 bottles per minute.

The investment has to be worthwhile

A linear drive system requires sophisticated control technology, making the purchase price relatively high. There are also costs associated with training personnel and optimising production flow, for example by executing the slowest processes twice. In many cases, these additional costs are quickly recovered through increased productivity, but not always. For example, in a recent application in a porcelain factory the slowest step in a production process for making cups was painting, which takes 30 seconds per cup. As a result, the throughput time for the entire process of finishing the cup is quite long.

At first glance, the installation of a linear motor driven system with individually controllable movers seems sensible in order to reduce throughput time and increase productivity. However, the purchase of an additional robot for painting the cups in order to increase the quantity of cups going through the machine could be in the region of £40K, in addition to the cost of the linear drive system. Investment in a linear drive system is not worthwhile in this instance; the flexibility it offers is not necessary for changing batch sizes and the faster production rate would not sufficiently recoup the initial investment.

Linked carriages mean a solid system

Another argument in favour of systems with linked carriages is in operating environments with consistently elevated operating temperatures. The electronics in linear motor systems are naturally sensitive to heat. Cooling mechanisms can be installed, for example in the base plate, but must be planned during the design of the system.

With the DTS, the drive can be positioned such that it is shielded from a heat source.

Overall, the simpler structure and less complex electronics of linked carriage systems makes them generally less sensitive to dirt, moisture and extremes of temperature. Linked systems can be advantageous wherever there are environmental conditions like this.

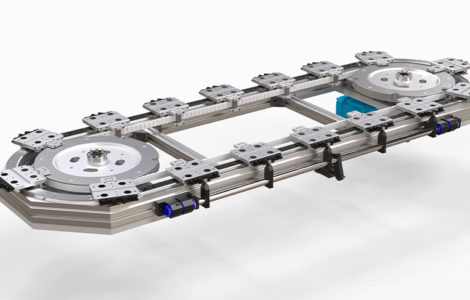

Hepco’s GFX –Guidance for Beckhoff XTS is suited to higher duty Beckhoff XTS applications.

Fewer carriages

The clearest reason for employing a linear motor driven system with individually controllable carriages is its ability to handle products of different dimensions. The ability to move carriages independently and ease of programming allows flexibility. In the case of systems with linked carriages, a new production cell may have to be designed and installed for a change in product type or size.

The cost of carriages to transport workpieces can also be an argument in favour of flexible driven systems. In some cases, carriages are so expensive to purchase that the cost of initial investment is recovered in linear motor driven systems where fewer carriages can be used compared to systems where carriages are mechanically linked. In a recent application in France for a leading cosmetics manufacturer, the number of carriages in the production cell was reduced by 80% when a linear motor driven system was specified.

The bigger picture is crucial

A linked carriage system such as the DTS is reliable, fast and low maintenance. If flexibility is not a primary objective and a standardised work processes with varying throughput times is not needed, the DTS is well placed to meet needs. For smaller companies in particular, a complete package such as DTS allows a clear overview of the costs involved and there are no significant follow-up costs. On the other hand, there are fewer and fewer ‘standard’ production processes in manufacturing.

The need for flexibility plays a growing role in all industries. In these cases, a linear motor driven system with guidance from GFX offers unbeatable advantages. Ultimately, the machine builder must look at systems costs and benefits as a whole. Both system types can be of advantage, depending on the application, the bigger picture must be taken into account. A balance between priorities and consequences must be struck whilst considering the long term requirements of the system.

Raccomandato per te

Contattaci

Modulo di contatto