Spie GmbH are responsible for the repair, maintenance and refurbishment of machinery for a leading train manufacturer in Germany. They were faced with a difficult problem: an old DUO welding system was broken down more than it was in operation and it was giving the company a constant headache.

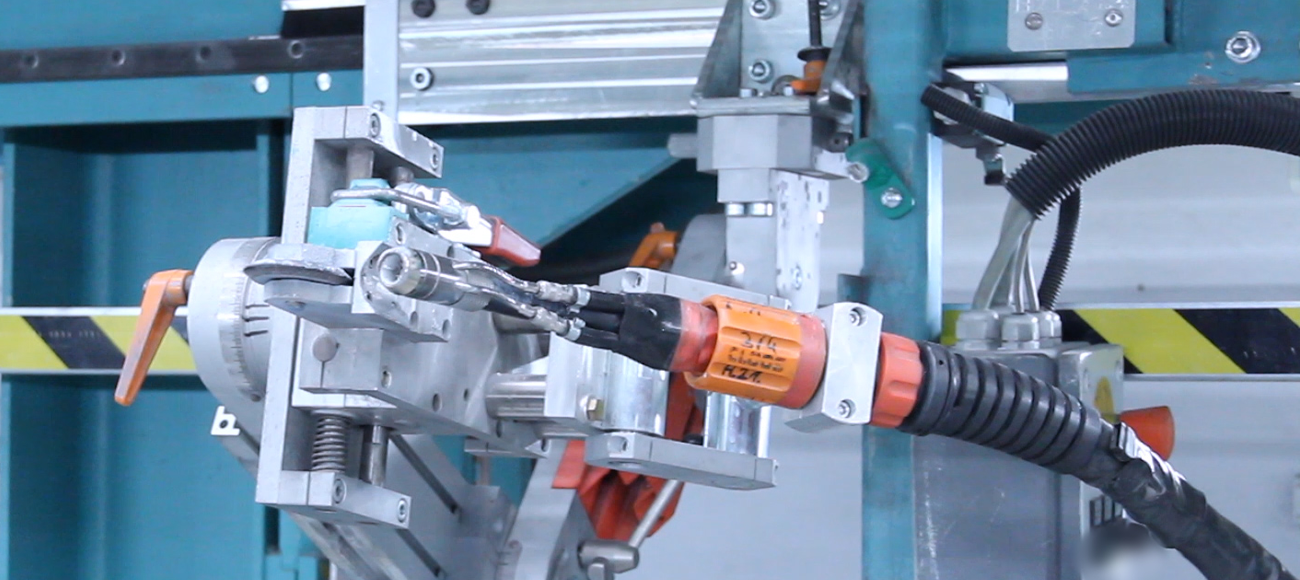

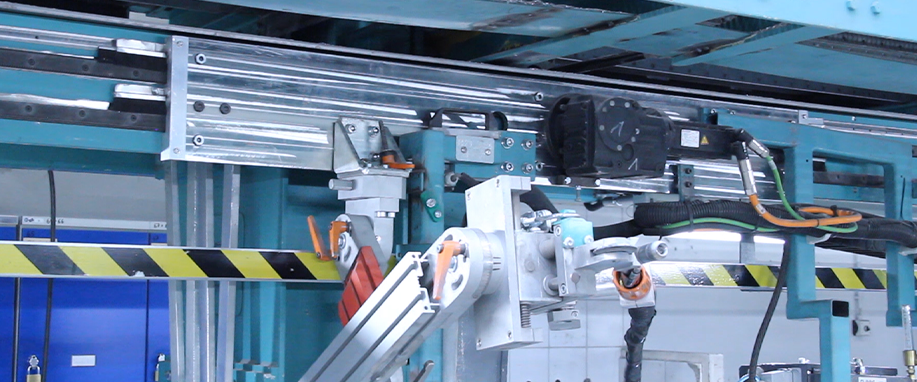

“We had to visit the customer almost every week, with two men working two or three shifts to maintain the welding machine. This was not economically viable for us and it was a huge problem for our customer as these failures meant the machine was often at a standstill, with a knock-on impact on other plant processes,” explains Günter Becker, Deputy Branch Manager of Spie GmbH. The welding system is enormous – 30 metres long and 10 metres wide. On each of the two welding machines four robots are mounted, two on the lower and two on the upper level. In a slow but constant movement, the robots weld aluminium assemblies up to 28 metres long to a wagon shell.

The robots are mounted to individual rack-driven carriages, each driven by a motor, which run on two guide rails.

Repair - yes, standstill - no

“We were looking for a linear guidance system that could operate in a very dirty environment, under constant load and with an unusually long track length. We needed a long-term solution that could be installed on the existing machine.”

“The problems we faced with the machine were multi-faceted,” says Becker. “From a construction point of view, the key difficulty was that the existing welding system from the 1990s had been built with an inadequate drive and guidance system. These were not suitable for heavy loads or such a dirty working environment. The existing rail systems had also been mounted on milled surfaces that were not perfectly flat. In addition, the guide rails were heavily worn due to the loads they had seen,” explains Becker. This caused not only the drive motors to regularly fail but also meant that the seams were not neat. In addition, dirt particles made their way into the recirculating ball bearings in the guide blocks for each welding robot – a common issue in this type of environment. This accelerated wear and also contributed to the frequent blocking of the motors.

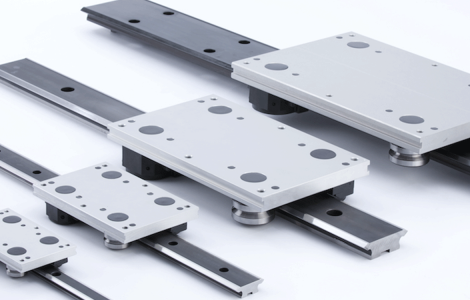

HepcoMotion's GV3 system

“For us, the question arose of how to obtain a smooth-running and reliable system without having to change the entire machine. This would incur high costs, probably in the region of 2 million Euros, and extended production down-time,” says Becker. A linear guidance system was required that could operate in a very dirty environment, under extreme and constant load, with a long rail length, minimal maintenance and that could be installed on the existing machine without interrupting production (a particular challenge).

This is where HepcoMotion came into play: Becker was familiar with the British linear guidance systems manufacturer from his previous employment at a specialist machine builder. “Our plan was to swap the existing guides one-by-one with a more appropriate system.” Becker worked on the project for over four months to ensure everything functioned correctly, so that he could convince his manager and customer of the feasibility and profitability of the project. “Due to the very special requirements of this application, only HepcoMotion came into consideration. To my knowledge, they are the only company that offer the flexibility to adapt to different sizes and lengths whilst coping with mechanical stresses and loads of the welding robots,” explains the skilled mechanical engineer. The rails, including carriages and bearings specified by Spie, are from HepcoMotion’s proven GV3 system. Approximately 500m of single-edge slides were used in the new design; the upper slides in each assembly were supplied with a rack to drive the carriages by motorised pinion.

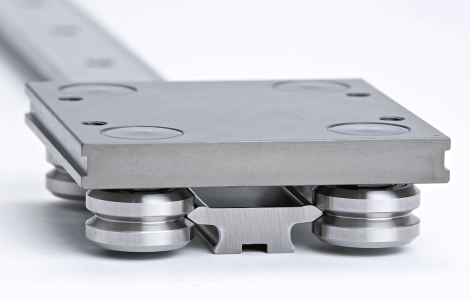

Double-row bearings, which are made in a single piece, were used on the carriages. “The one-piece design ensures no dirt can penetrate into the bearings. The V-guide principle also ensures that dirt particles are transferred away from the running surface as the bearings move along the slide,” explains Thorsten Pfau, Sales Manager for HepcoMotion in Germany. “These bearings have high load capacities, especially in the radial direction. In this case, this was of great importance – the mass of the welding robot and carriage is about 220kg.”

“We worked in close collaboration with the Technical Sales team in Hepco's German office. They were extremely helpful in solving this challenge and ensuring longevity of the system can be achieved.”

“It was also important that the bearings could be manually re-adjusted, without great effort, to take away any play that develops as a result of wear from the continuous high load. HepcoMotion’s V guide systems can be quickly and easily adjusted to remove any play that has occurred thanks to the eccentric adjustment facility.

It was a lot of work for the Spie team to update the machine whilst production continued; work was carried out whenever a welding robot was not in use. “The old rails had to be disassembled and the mounting surface fully cleaned so that 5,500 new holes could be drilled for mounting the new guidance system – and all by hand! HepcoMotion’s rails are supplied in a maximum length of 4 metres, but are easily joined to make the total 30m length of the system. Alignment of each rail was of particular importance to ensure a good join between teeth in the rack and to provide a smooth movement of carriage across each joint in the slides. With the assistance of a Leica laser tracker for surveying, we were able to accurately align the rails with a deviation of less than 50 microns per slide. This means the systems are running completely trouble-free!” explains Becker proudly, who was worked with his team to overhaul the machine over a period of five months.

It was definitely a lot of work, but the investment paid off quickly – trouble-free running of the welding robot was one of the main criteria for Spie’s customer. The machine could be updated without production downtime and there was no need to purchase a replacement machine. “Of course, it was great that not only did we get great quality from HepcoMotion, but also a reasonable price for the components” adds Becker.

Raccomandato per te

Contattaci

Modulo di contatto