Positioning 28 individual fixtures for the assembly of automotive temperature sensors requires a consistent level of precision if rejects are to be avoided.

Traditional conveyor type systems used in the past have not provided the level of accuracy needed with too many rejects being seen from the assembly process. End users Kia and Hyundai have stringent quality standards that can only be achieved on precise and robust assembly equipment.

Solution

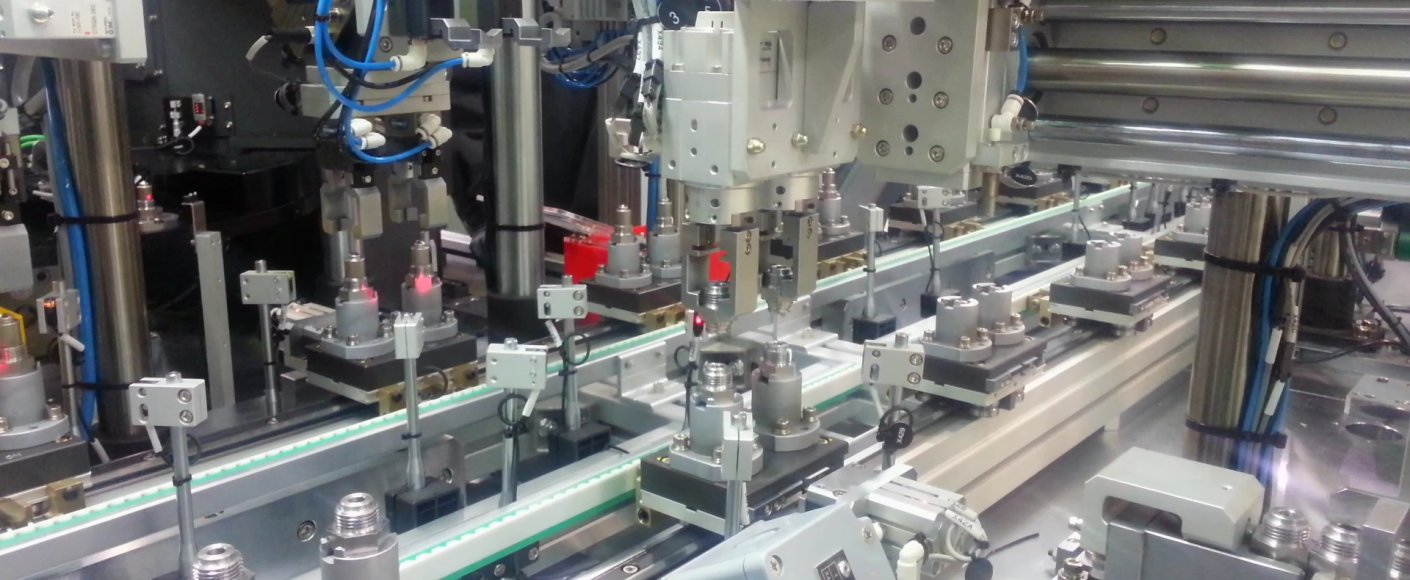

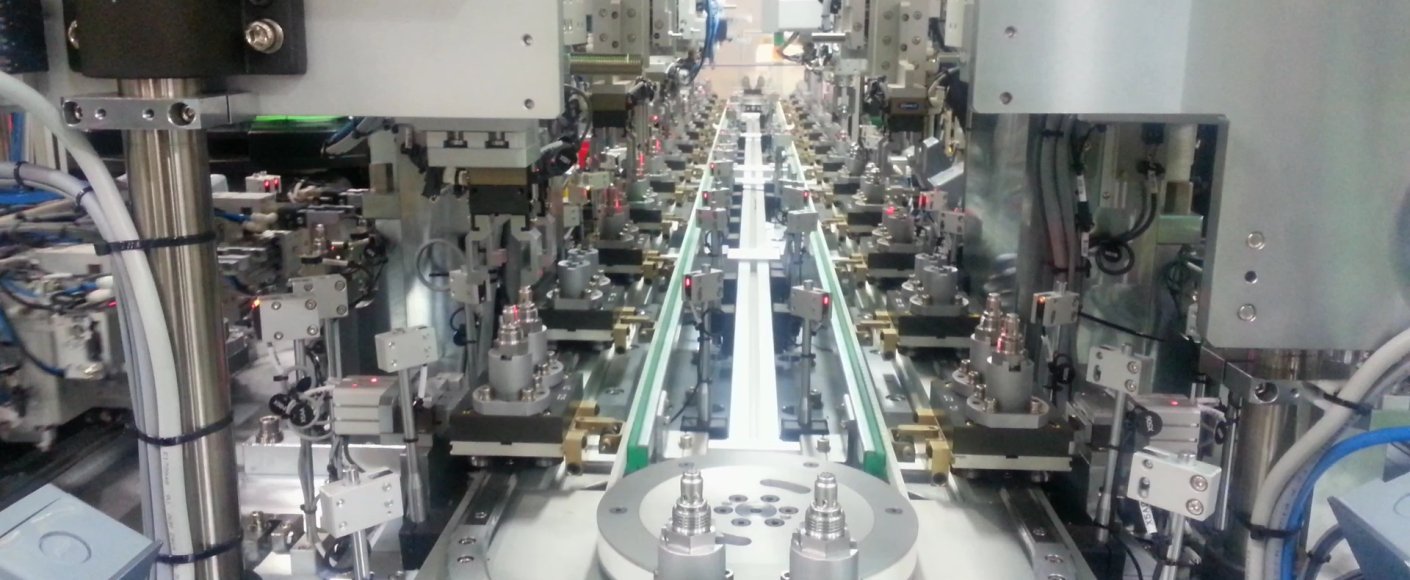

A highly versatile Hepco DTS track system, oval shaped with 28 carriages attached to a common belt drive with one driver and one idler pulley. The customer locates fixtures to each carriage that are, in turn, guided accurately around the track. The DTS also incorporates a locking system capable of +/- 0.1mm positional accuracy, well within the application assembly requirements.

Scope of supply

DTS25-351 x 3904mm long, 351mm dia end radii, complete with 28 carriages, pulleys and belt. Integral lubrication system included to ensure a long and trouble free service life.

Result

A consistent assembly process with no rejects together with a much improved production throughput. The improvement in the component quality is a direct result of the better positioning accuracy of the carriages offered by the DTS. Another factor is the ability of the carriages to accept the necessary assembly forces whilst maintaining goodlevels of rigidity. The DTS is a right first time solution for this customer.

Recommended for you

Contact us

Tel Sales Enquiries +44 (0)1884 257000 General Enquiries +44 (0)1884 243400

Email [email protected]

Address

HepcoMotion Head Office

Lower Moor Business Park

Tiverton Way

Tiverton

Devon, EX16 6TG

Contact Form