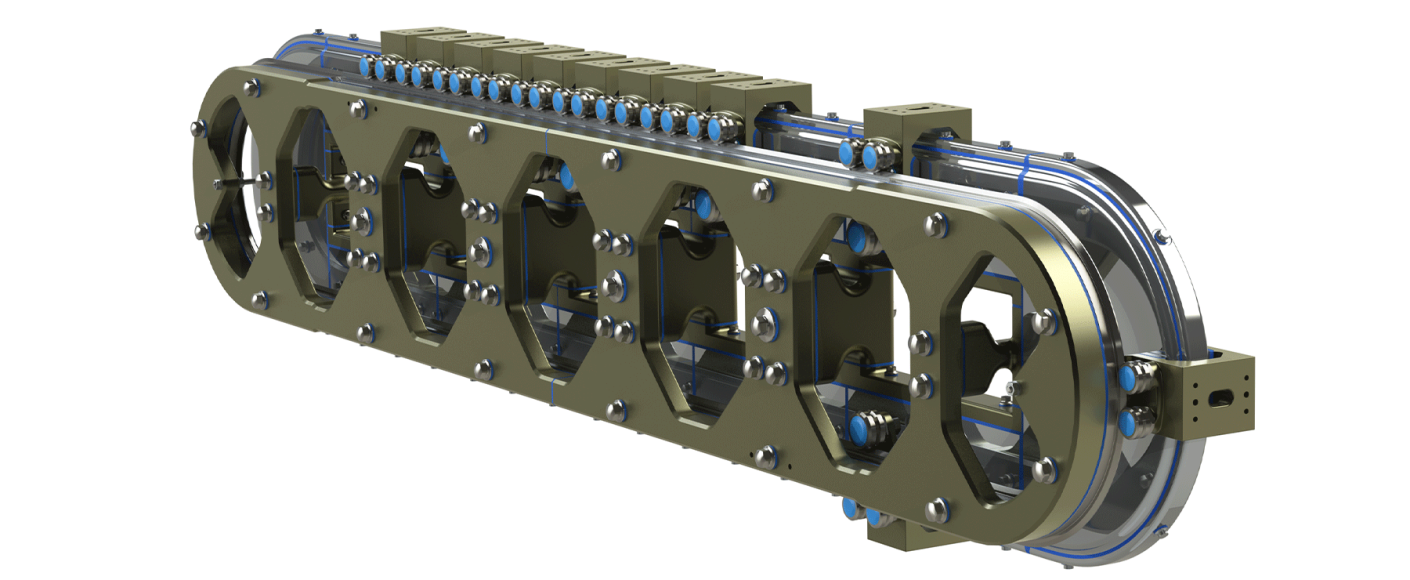

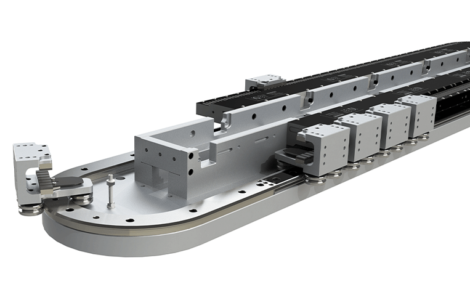

Designed for the food and pharmaceutical industries, GFX Hygienic is a precise and durable guidance system for the Beckhoff XTS Hygienic Design, achieving highly flexible motion solutions with optimal cleanability.

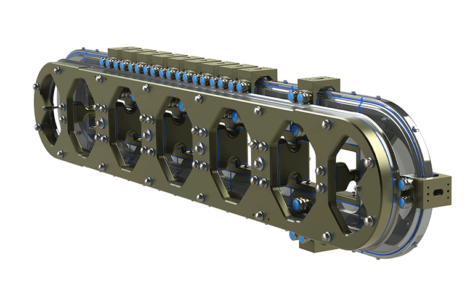

Cleandown and washdown – GFX hygienic is available in two versions to suit differing customer needs; cleandown and washdown.

Cleandown for wet cleaning – Using a structure that is very similar to a standard GFX, this version has been modified to fit the Hygienic Design motors, allowing wet cleaning with benign liquids.

Remove surface contamination – The cleandown version is designed for pharmaceutical, food and other processes where the system requires wet cleaning to remove surface contamination.

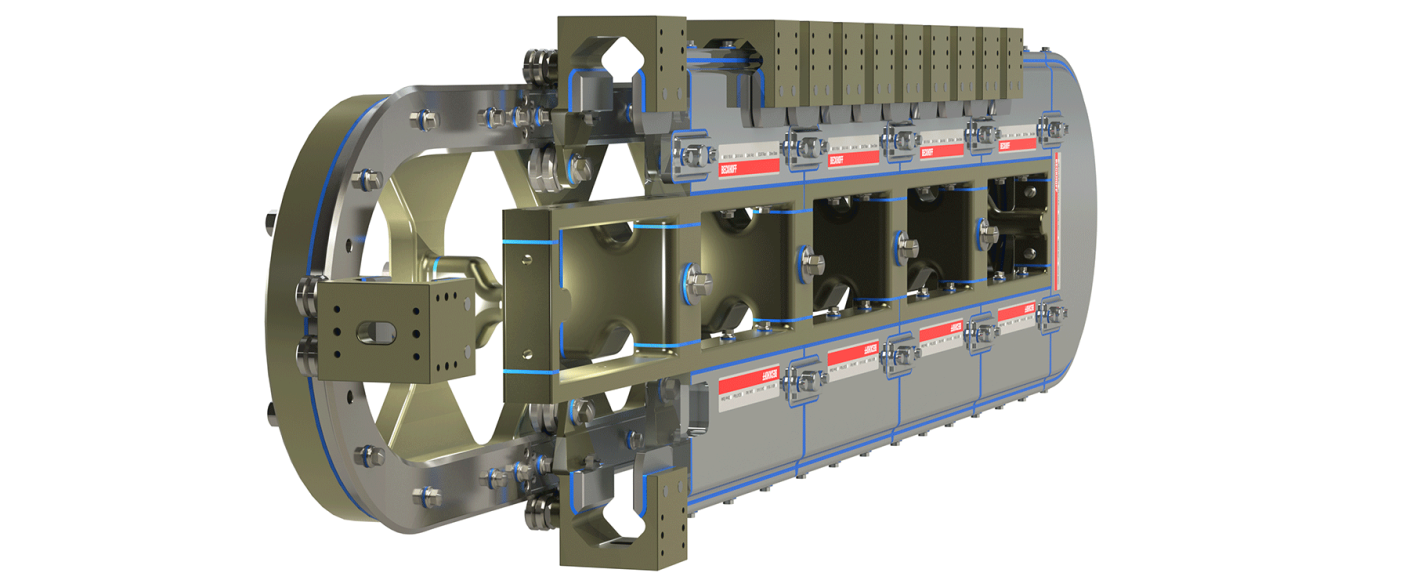

Washdown for cleaning in place – Simple cleaning is possible in hygienically demanding environments, including foaming agents, hot washing and pressure washing.

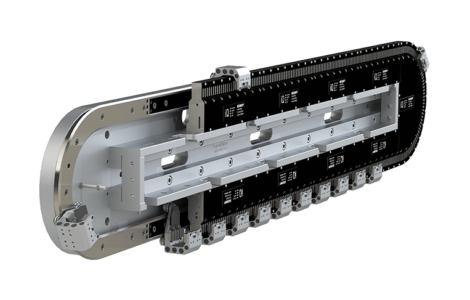

Access to all surfaces – The construction allows complete access to all surfaces, removing pooling traps and enabling optimal cleanability so nothing accumulates.

No tiny gaps – Joints between all components are sealed and the bearings are protected against lubricant egress and ‘flushing’ with a solid cover and labyrinth seals.

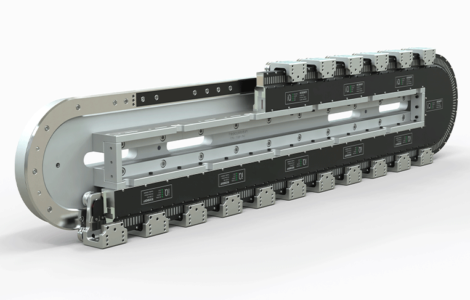

HepcoMotion and Beckhoff – HepcoMotion works in partnership with Beckhoff to create the GFX system, a high-end track system that provides the support and rigidity required for precise XTS applications.

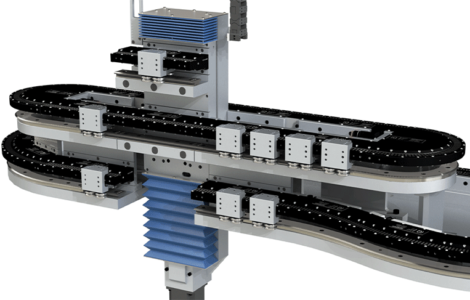

Flexible – The Beckhoff XTS Transport System uses linear motor technology to independently drive movers around a track. This allows work processes of different duration to be combined, on the fly product changes, and the addition or removal of workstations as needed.

Precise and reliable – GFX provides the transport path and mechanically guides the movers along the motor modules at the defined speed, with great precision, ensuring accurate alignment and resistance to deflection.

Long system life – GFX is designed to accommodate complex, high-speed motion profiles requiring extended duty cycles.

- GFX can be supplied fully assembled, with Beckhoff motor modules, mover magnets and mover encoder flags, partially assembled, or as a kit of components

- Cleandown is similar to a standard GFX track system and uses the same base plate geometry

- Washdown should be designed into the equipment in such a way that the system will drain and access for cleaning is maintained

- A simplified lubrication system enables use in high duty cycle production environments, food compatible lubricants can be used

- The system offers a superior positional accuracy of +/- 0.10mm even at high speed

- The number and spacing of the movers is flexible

- To maximise system life, GFX includes integrated bleed lubrication

Contact us

Tel Sales Enquiries +44 (0)1884 257000 General Enquiries +44 (0)1884 243400

Email [email protected]

Address

HepcoMotion Head Office

Lower Moor Business Park

Tiverton Way

Tiverton

Devon, EX16 6TG

Contact Form