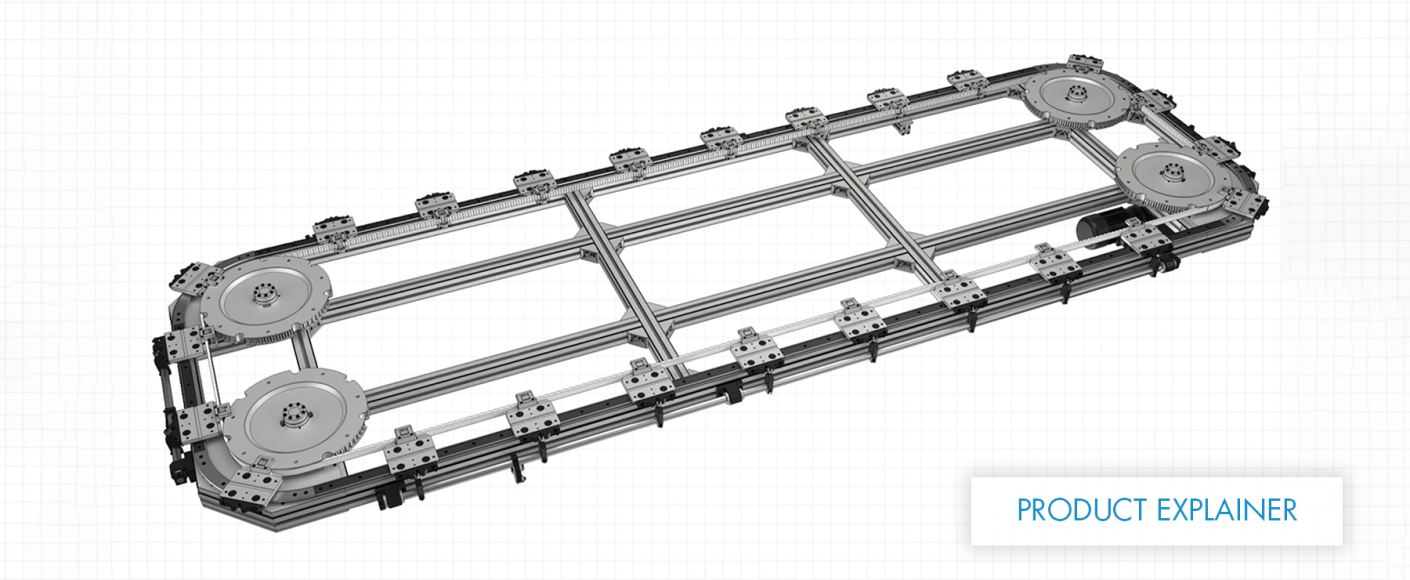

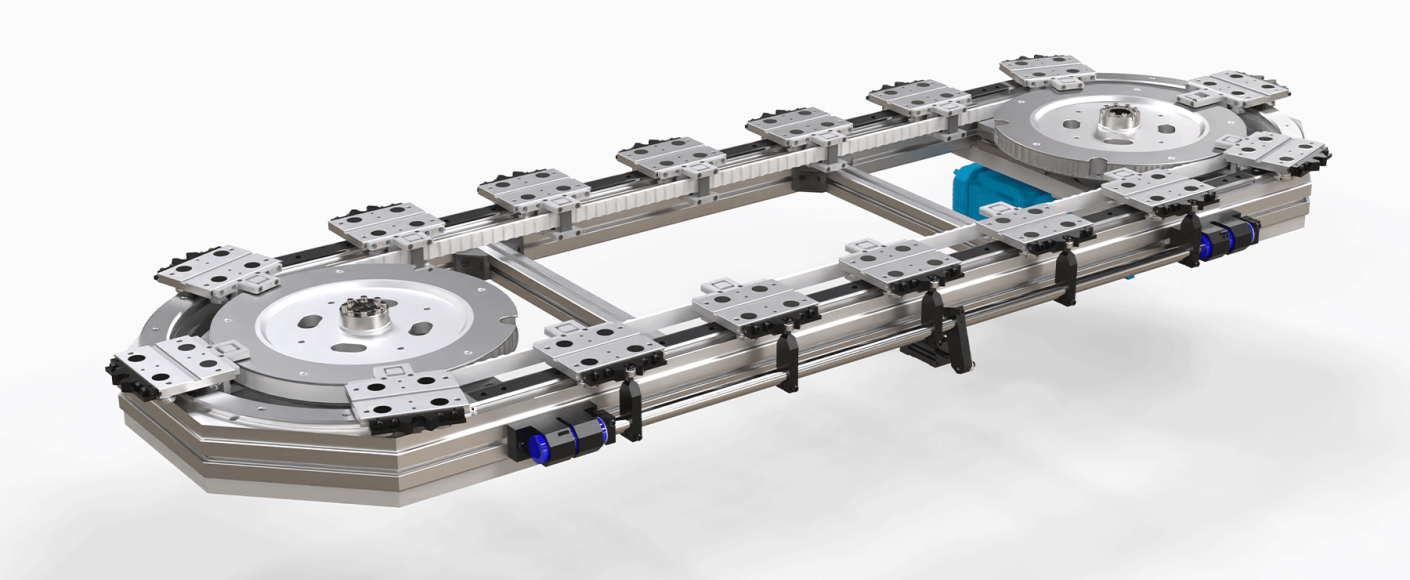

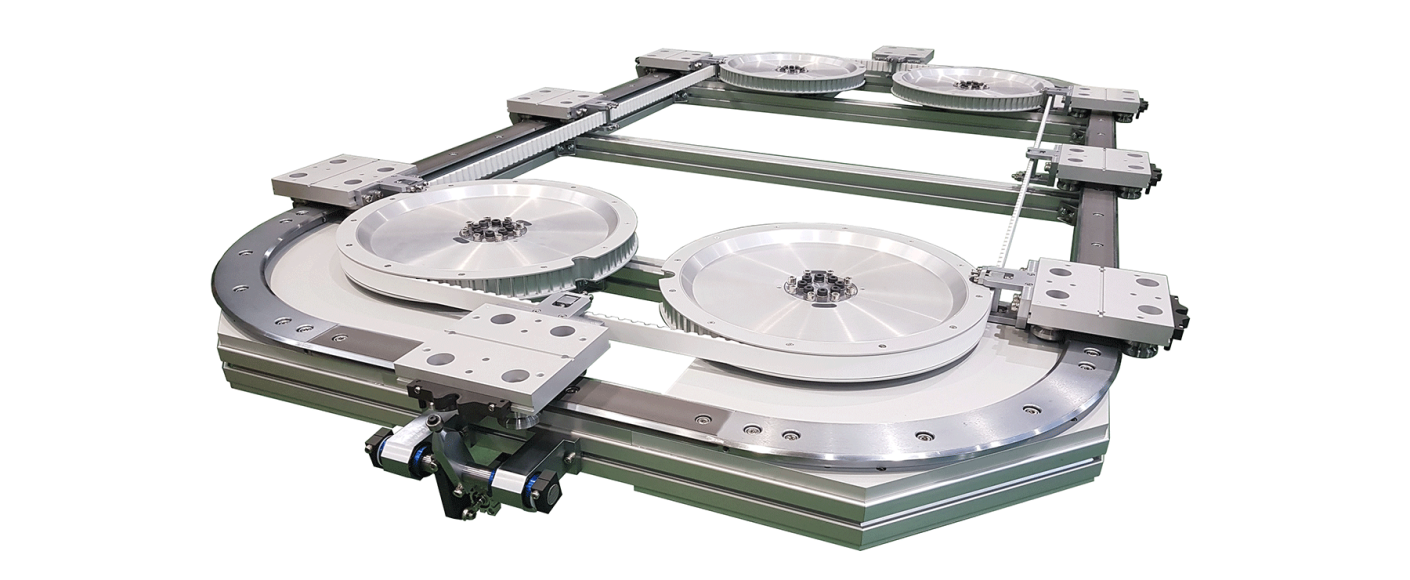

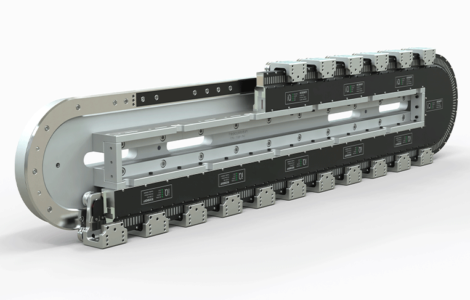

Designed for higher loads requiring speed and accuracy, DTS+ is a ready to fit track and positioning system ideally suited for modern automation processes.

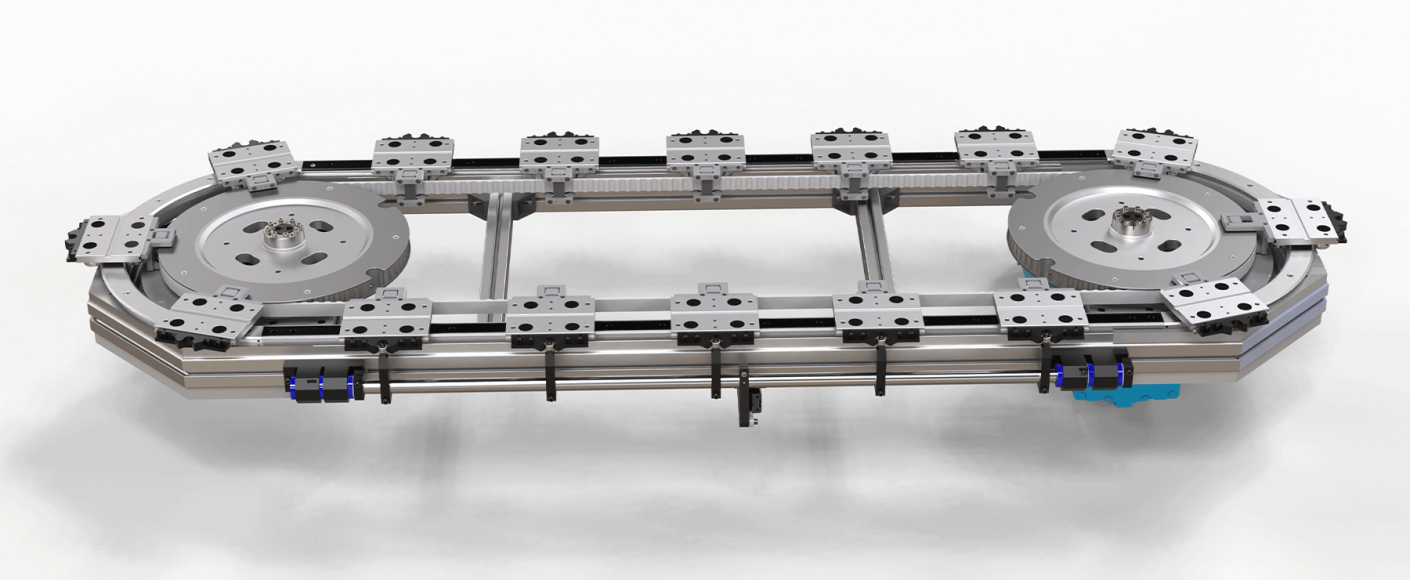

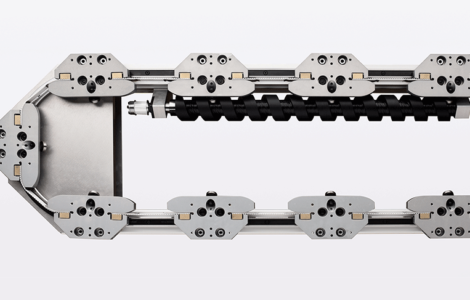

Speed for higher loads – A high strength belt, together with a specially designed belt-fixing mechanism, ensures carriages will not disengage, allowing higher driving forces and higher loads.

A solution for vertical applications – DTS+ is capable of much higher drive forces due to the robust fixing clamp, which means that carriages will not disconnect if a certain force is exceeded when pushing a payload vertically.

Reduced process cost – Enables complex production routing and disconnected processes to be contained within one single continuous loop.

Turnkey production cell solutions – HepcoAutomation can provide standard drive and control systems for any production cell application, managing the project from concept to completion. Find out more here.

Loads up to 10kN – Multiple size options available, allowing for higher loads up to 10kN.

Reduced design and installation time – As a ready to fit system, DTS+ minimises design time and cost and is simple to install and operate.

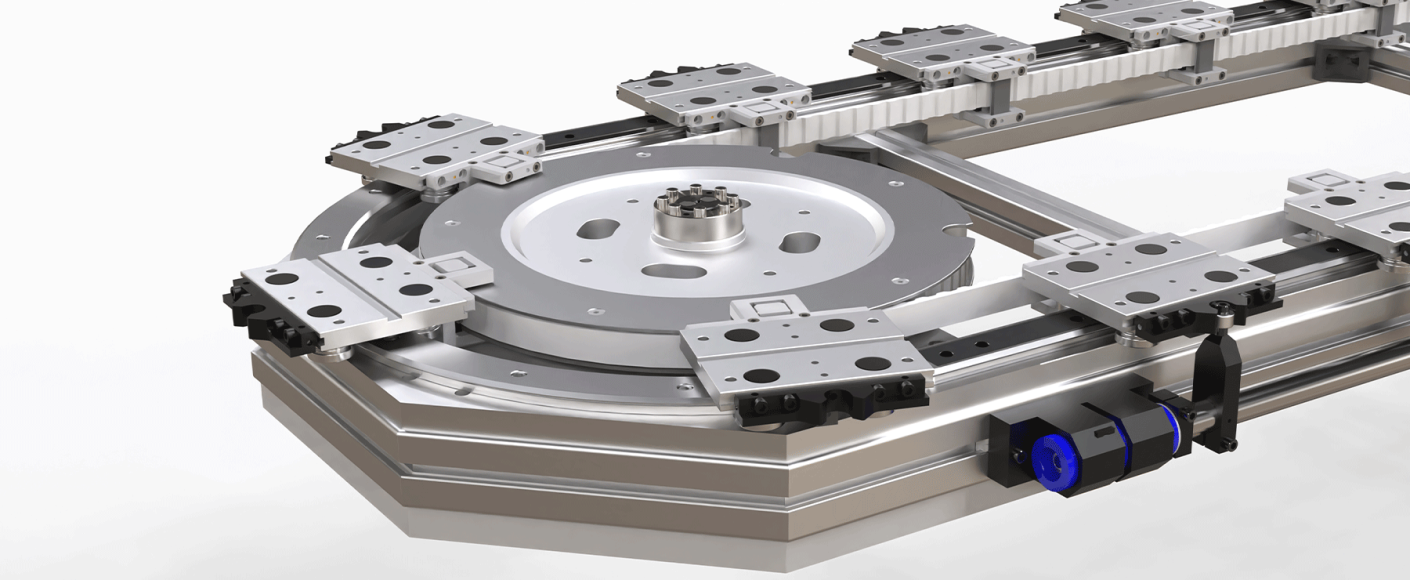

Precise and repeatable – A carriage locking option aligns specific carriages to a repeatable position anywhere along any straight section of the circuit to +/-0.05 mm.

Reduced downtime – Hepco’s bleed lubrication system provides constant lubrication to the contact surface between the track and V bearings, eliminating the need to stop production lines regularly for re-lubrication.

Suitable for hostile environments – Thanks to HepcoMotion’s V guide technology, the system works well in production environments that produce dust or dirt particles.

- Easily incorporated into a multi-function machine as a transfer or positioning system

- Available in an oval or rectangular shape

- Wide choice of system sizes with unlimited length. The specific layout is adapted to customer requirements

- Corrosion resistant version available

Contact us

Tel Sales Enquiries +44 (0)1884 257000 General Enquiries +44 (0)1884 243400

Email [email protected]

Address

HepcoMotion Head Office

Lower Moor Business Park

Tiverton Way

Tiverton

Devon, EX16 6TG

Contact Form