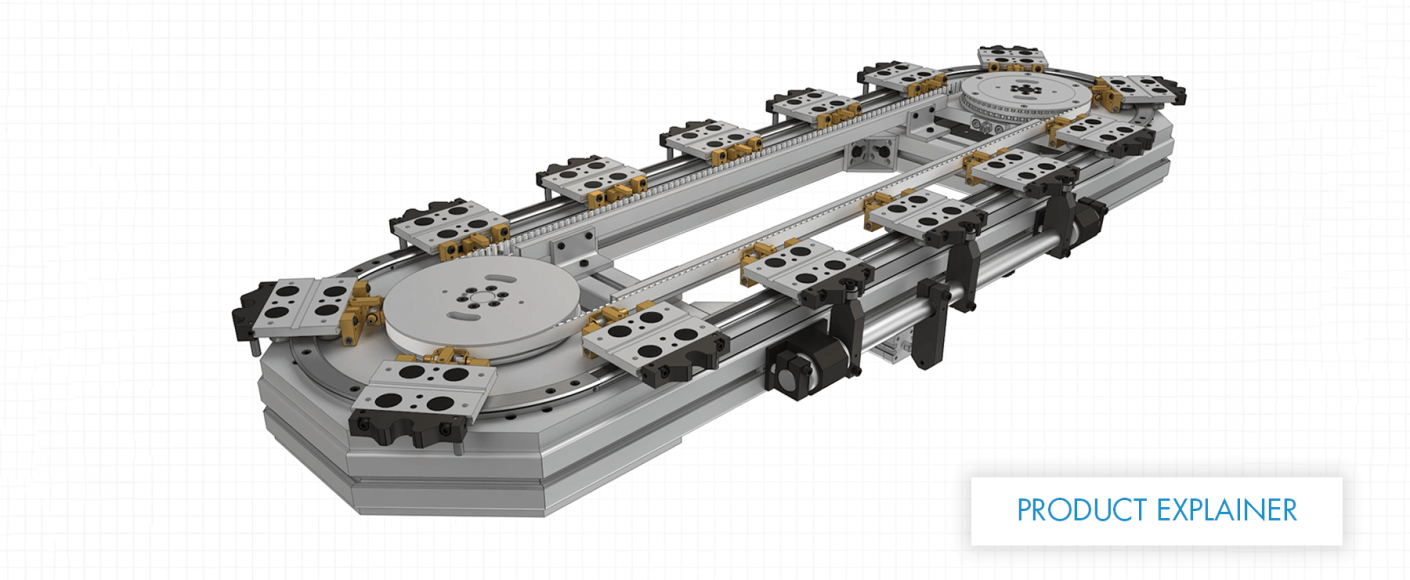

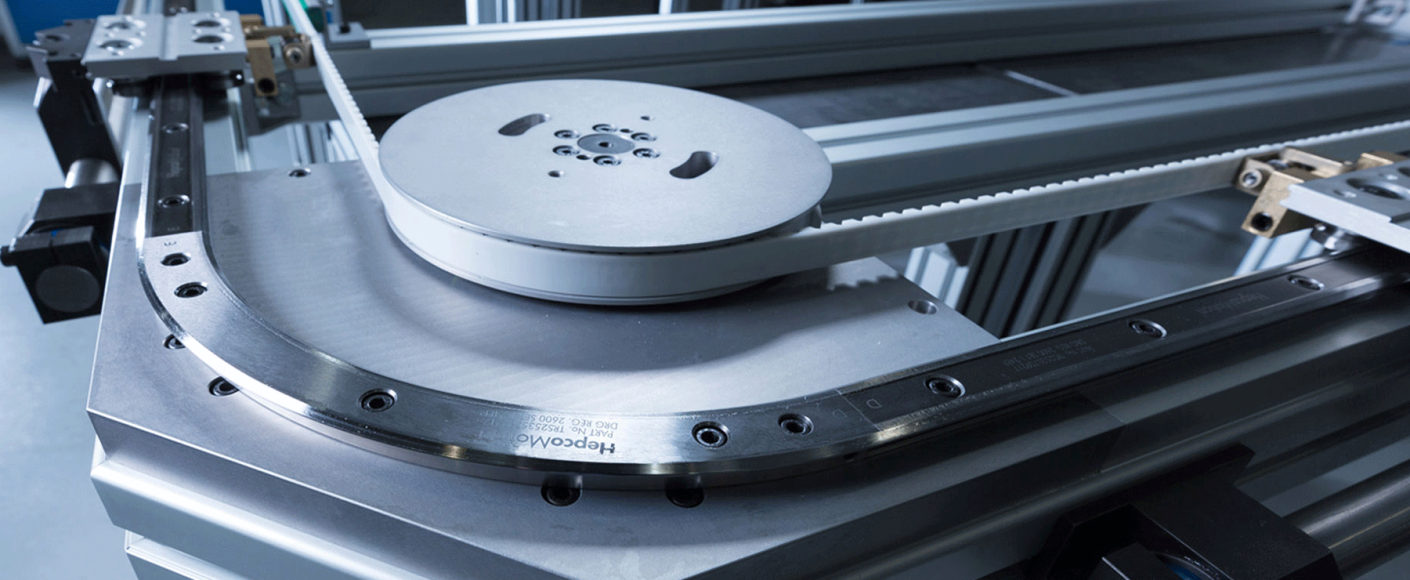

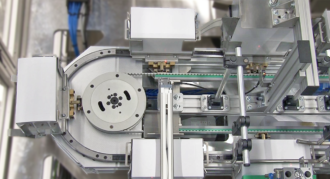

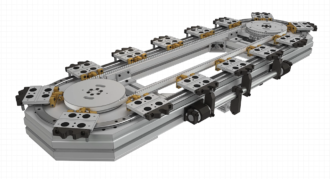

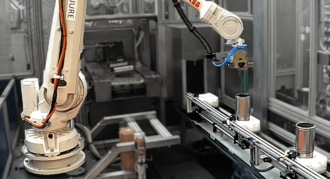

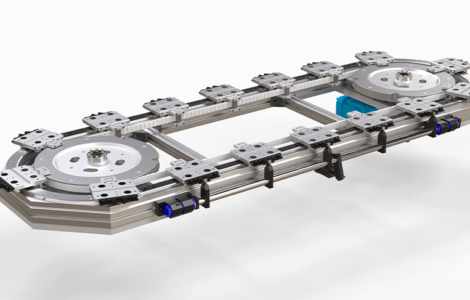

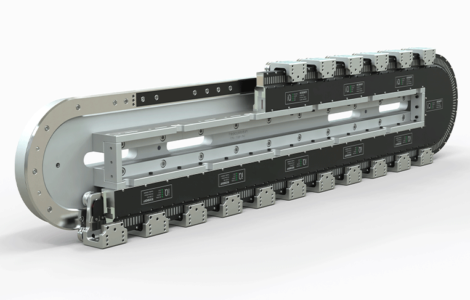

DTS belt driven track systems are at the core of modern automation processes, moving products from station to station in an accurate, repeatable, and controlled manner.

Reduced design and installation time – As a ready to fit system, DTS minimises design time and cost and is simple to install and operate.

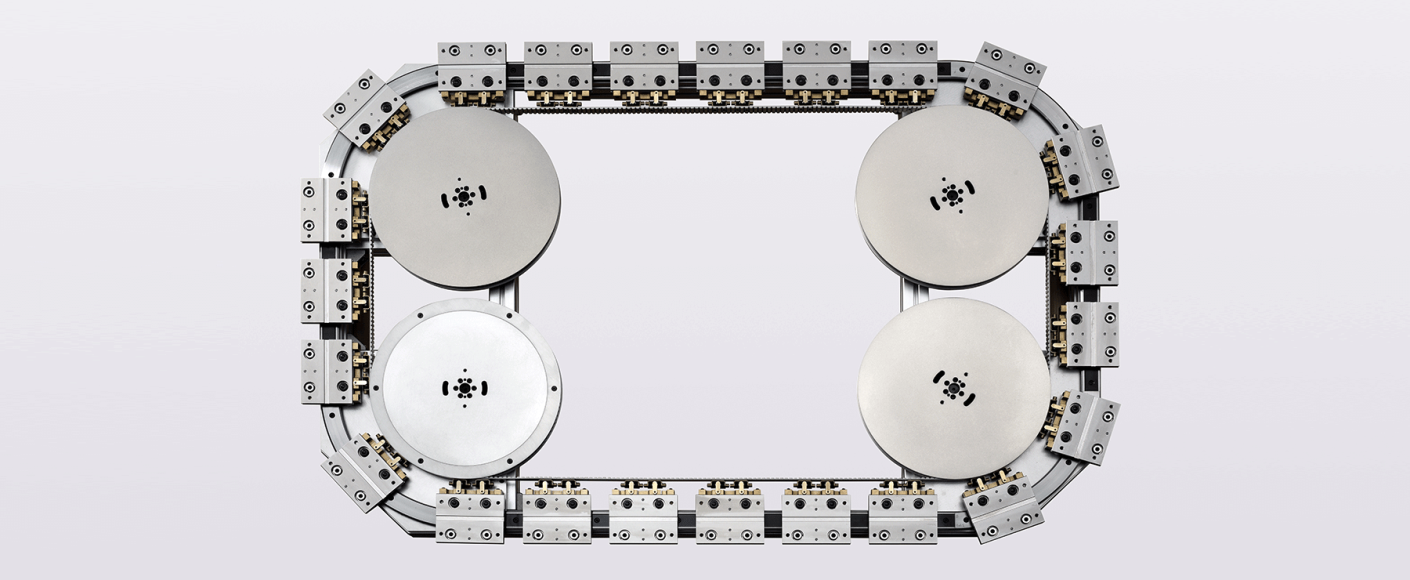

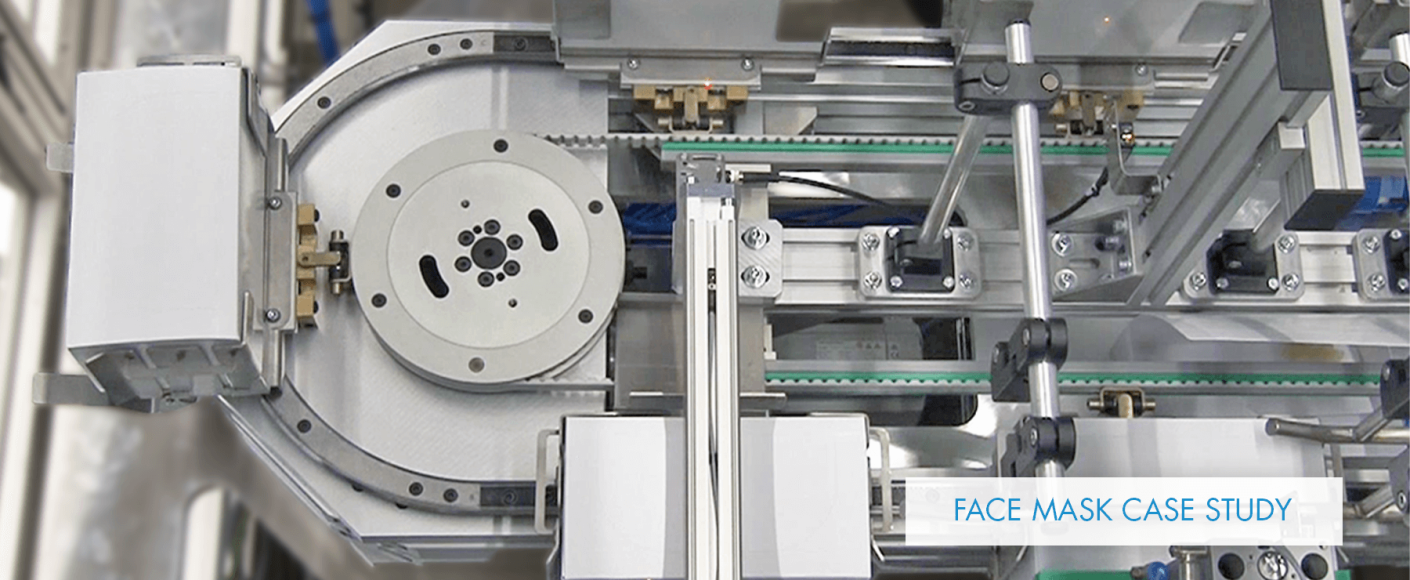

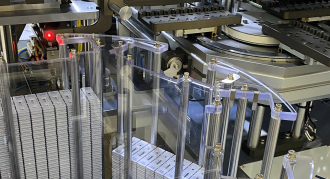

Reduced process cost – Enables complex production routing and disconnected processes to be contained within one single continuous loop.

Perfect for – the transport of uniform batch sizes and light to medium loads in continuous or indexing operations across all industries.

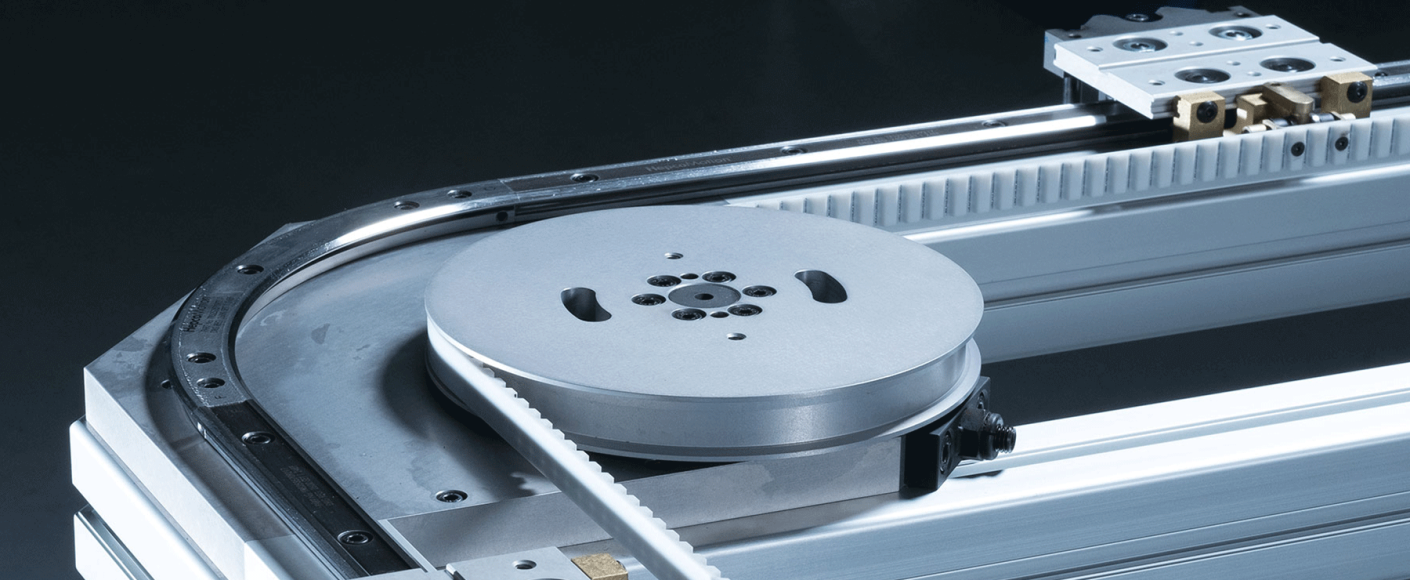

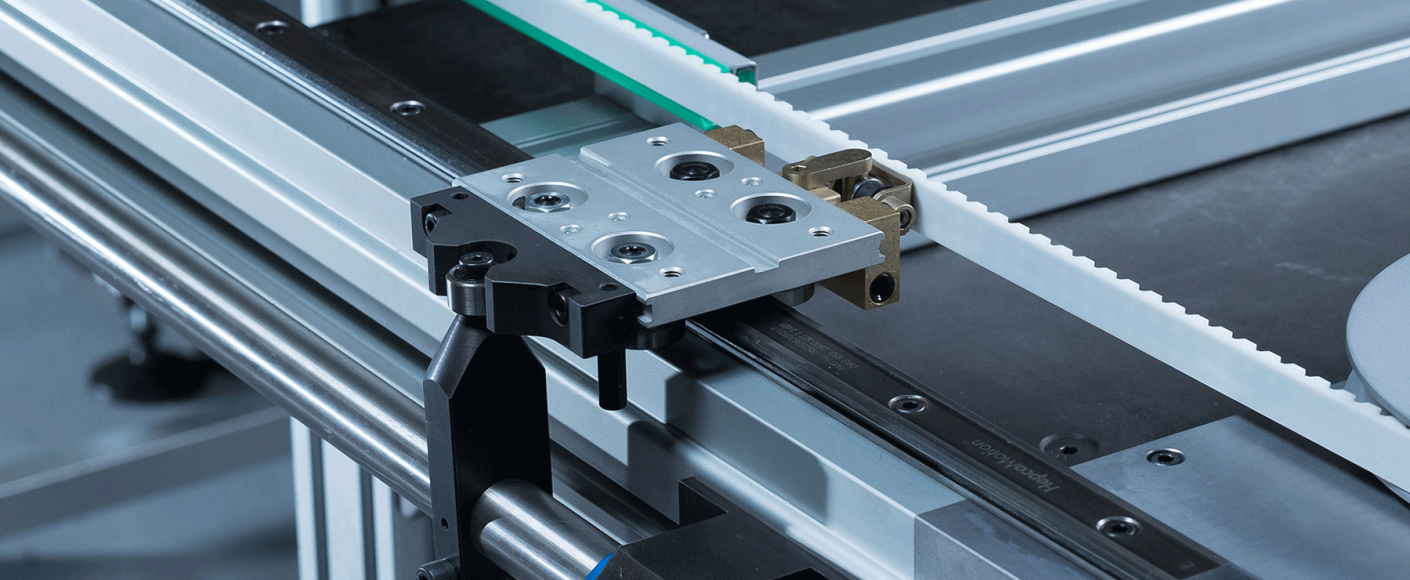

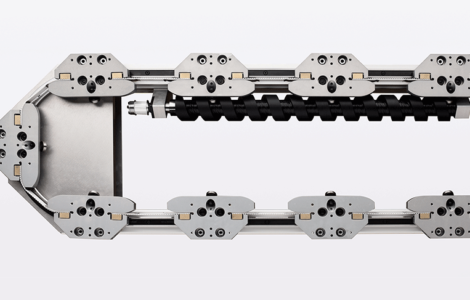

Precise and repeatable – A carriage locking option aligns specific carriages to a repeatable position anywhere along any straight section of the circuit to +/-0.05 mm.

Prevents system overload – DTS includes a trip latch mechanism that disengages and prevents belt damage in the event of system overload.

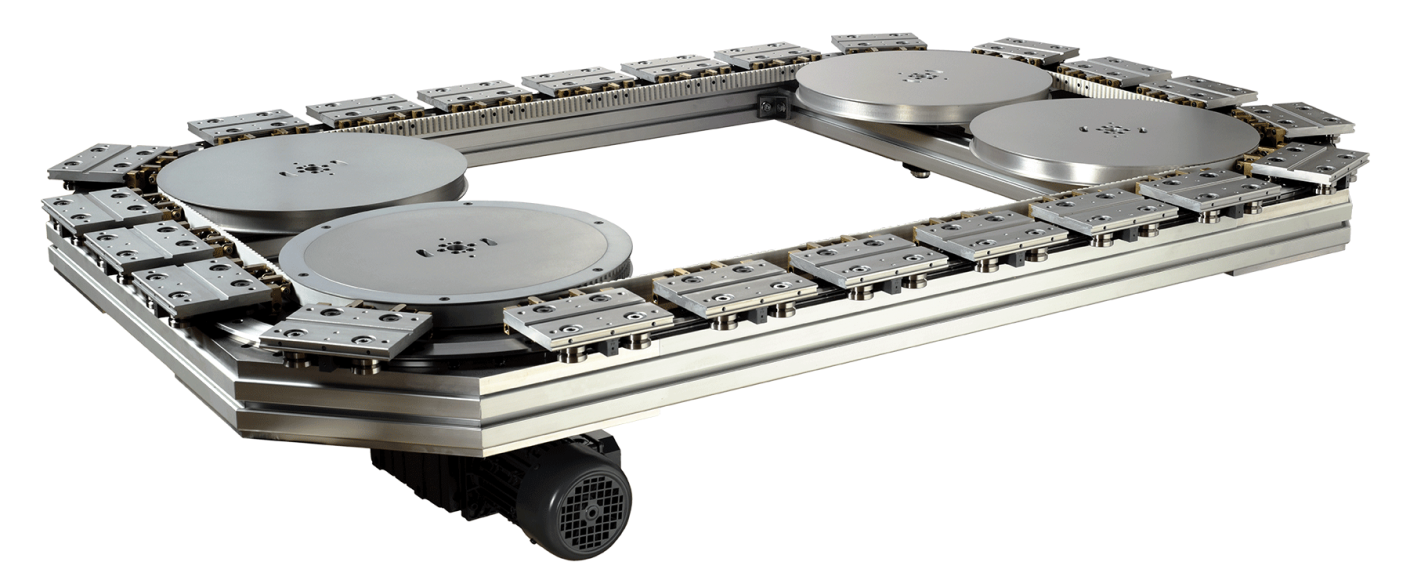

Space saving – DTS can integrate workstations anywhere along, and within the centre of the system, thereby minimising the machine footprint.

Reduced downtime – Hepco’s bleed lubrication system provides constant lubrication to the contact surface between the track and V bearings, eliminating the need to stop production lines regularly for re-lubrication.

Suitable for hostile environments – Thanks to HepcoMotion’s V guide technology, the system works well in production environments that produce dust or dirt particles.

- Available in two track sizes (25mm and 44mm)

- Can operate in a horizontal or vertical position, offering design flexibility

- Can be integrated into a pre-existing system

- A keyed input shaft allows for fitting of motor options or alternative drive solutions

- Available in an oval or rectangular shape

- Wide choice of system sizes with unlimited length. The specific layout is adapted to customer requirements

- Corrosion resistant version available

Contact us

Tel Sales Enquiries +44 (0)1884 257000 General Enquiries +44 (0)1884 243400

Email [email protected]

Address

HepcoMotion Head Office

Lower Moor Business Park

Tiverton Way

Tiverton

Devon, EX16 6TG

Contact Form