This large manufacturer of insulation products had the unenviable task of positioning mould tools from a 50m long conveyor into various filling stations under extremely hostile conditions.

Many linear systems would not last in an atmosphere filled with fine fibres that covered all surfaces and impregnated covers. A system able to work in such adverse conditions with a long service life would be vital. The application required a 10m X axis and a 2.5m Z to transfer the mould tool from the conveyor to the filling machine and a XY table movement of 2.7m to place the mould under the required filling nozzle.

Solution

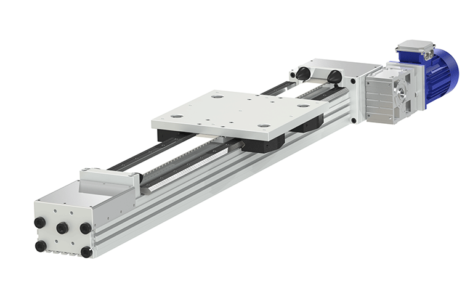

A combination of a Heavy Duty beam 10.6m long with common rack driven carriage to enable direct fitting of the Z axis offered an ideal robust solution that would be unphased by the conditions. Both these axes function with only cap wipers to wipe debris from the slides and protect the bearings. Belt driven systems for both XY table movements were protected by bellows as this is where most of the contamination takes place.

Scope of supply

X-Z Gantry

X-Axis

Size 33 HD beam, 10,600mm long fitted with size 25 slides, one with rack. Common X-Z rack driven carriage assembly with fitted gearboxes. Adapter plates on both gearboxes for fitting customers servo motors.

Z-Axis

Size 25 compact HD beam 2500mm long with size 25 slides, one with rack, beam assembly mounted to X-Z carriage assembly. Axes fitted with bellows and cable chains.

X-Axis

Two Size 95 HDLS units, 2700mm beam lengths. One unit fitted with gearbox and adapter plate, second unit driven through connecting shaft. Both units supplied with extended carriages for mounting Y-axis.

Y-Axis

One size 95 HDLS unit, 2700mm beam length with fitted gearbox with adapter plate.

Slave unit to suit above.

Both axes fitted with bellows and cable chains.

Result

Improved productivity with no ongoing concerns about whether the system will perform in the hostile conditions. An effective solution able to work over extended periods with no maintenance.

Recommended for you

Contact us

Tel Sales Enquiries +44 (0)1884 257000 General Enquiries +44 (0)1884 243400

Email [email protected]

Address

HepcoMotion Head Office

Lower Moor Business Park

Tiverton Way

Tiverton

Devon, EX16 6TG

Contact Form