This manufacturer of gas bottles needed a special purpose labelling machine to identify each bottle by needle printing directly to the bottle outer shell.

The key requirement was that the bottle had to be rotated at a consistent smooth rate in order to maintain a high quality print. In addition the 200 kg bottles have to be loaded from floor level so in order to avoid specialised lifting equipment it was important to keep the overall height of the base as low as possible.

Solution

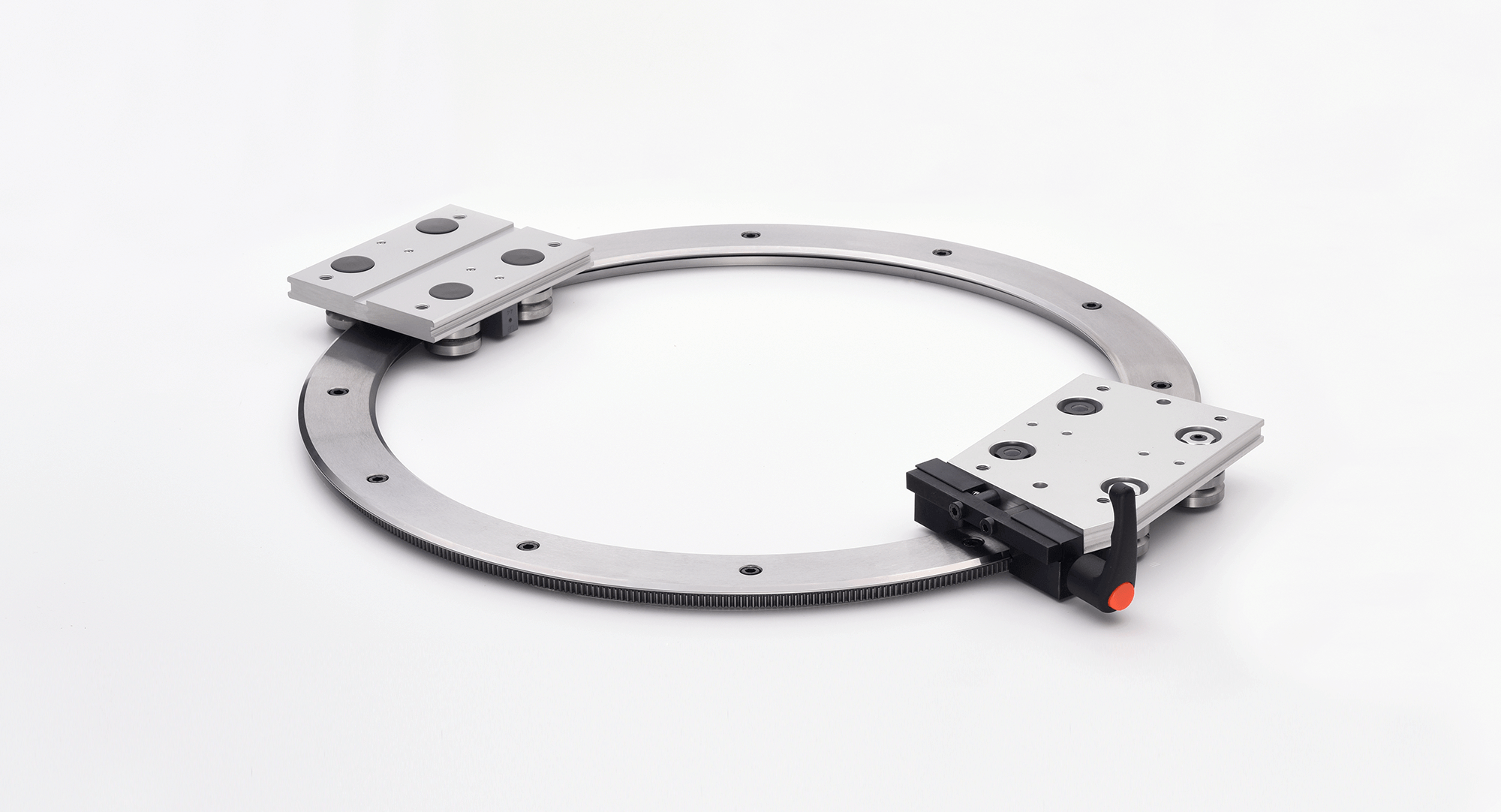

RIS 285 timing belt ring fitted into the base with a location ring to mount the bottle to. The timing belt ring was chosen so that a smooth constant rotation of the ring would be achieved with no “lost motion”. Size 25 double row V groove bearings were used 4 per ring to support the load of 200kg. The double row version has improved rigidity over the twin V groove bearing often used in similar applications where lighter loads are involved. The whole arrangement was fitted into a base height of 45mm making manual loading possible with the aid of a small ramp.

Scope of Supply

1 x RIS285 TB timing belt ring, 1 x TPAT5VK6T40 Timing pulley, 1 x 16AT5VKS Timing belt, 2 x RSJ25CDR, 2 x RSJ25DEDR V groove bearings.

A quiet smooth rotational movement achieved through the use of standard catalogue parts from the PRT2 catalogue. Print quality has been improved and the throughput of bottles is much faster since the introduction of a bespoke labelling machine.

Recommended for you

Contact us

Tel Sales Enquiries +44 (0)1884 257000 General Enquiries +44 (0)1884 243400

Email [email protected]

Address

HepcoMotion Head Office

Lower Moor Business Park

Tiverton Way

Tiverton

Devon, EX16 6TG

Contact Form