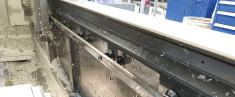

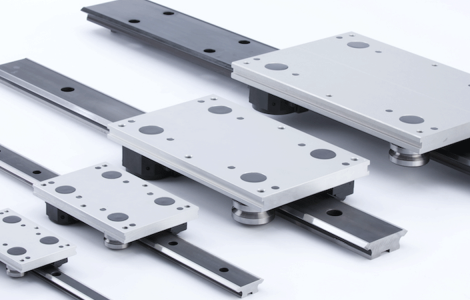

Metal chips, cutting fluids and manufacturing debris make CNC machines a challenging environment for linear motion products, with a high risk of costly downtime. The doors and tool changers have to open smoothly, many times per day, despite enduring harsh environmental factors. Not all linear motion products can cope with these demands, whilst also providing reliability, long life and minimal maintenance. Bishop Wisecarver’s DualVee® guide wheels and linear track, distributed by HepcoMotion throughout Europe, confidently does just that.

DualVee® is an ideal choice to reduce the maintenance requirements of CNC tool changers and doors. The matching V surfaces on the guide wheels and track wipe away any oils and debris as they roll, allowing the linear motion components to effectively clean themselves.

The machine doors and tool changer must perform smoothly and reliably, even when cutting fluids allow metal shavings to stick in problem areas. The linear motion components of the tool changer must also provide sufficient rigidity and load capacity for the tool head.

DualVee® guide wheels mounted on eccentric bushings can be adjusted to fit throughout the system’s life, and to provide the right running feel for each application. As a result, the doors move smoothly with every operation, and the tool changer requires less maintenance.

Recommended for you

Contact us

Tel Sales Enquiries +44 (0)1884 257000 General Enquiries +44 (0)1884 243400

Email [email protected]

Address

HepcoMotion Head Office

Lower Moor Business Park

Tiverton Way

Tiverton

Devon, EX16 6TG

Contact Form