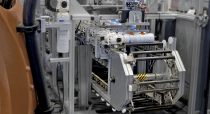

Robotronic AG, focuses on individual automation solutions for the pharmaceutical packaging industry and for this application they needed an accurate feed system to position glass vials in sets of 5 so they could be located into blisters, at a rate of 5 every second.

A follow on operation was to pack the finished packages in sets of 10 into boxes. The feed system needed to work at high speed and coordinate position with two parallel robots. Positional accuracy was vital as the glass vials would easily break if there was any inaccuracy of position of the feeding system.

Solution

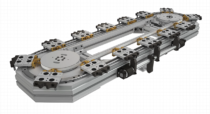

A Dynamic Track System ( DTS2M) with 21 linked carriages acted as the feeding system with the carriages holding the fixtures for positiong the vials. At any one time 6 carriages needed to be placed within a positional accuracy of +/- 0.2mm. Driving of the linked carriages was by a screw drive ( scroll ) with the 6 carriages that required accurate positioning all being located in the scroll at the same time.

A Mitsubishi servo motor plus control system was supplied by Robotronic to enable accurate position of the blisters and vials.

Scope of Supply

DTS2M customised

Result

The modular design of the DTS2 system is an ideal choice for an application requiring high positional accuracy and a demanding duty cycle. DTS2 comes with a bleed lubrication system that reduces maintenance requirements to almost nill.

The ability to accurately position 6 carriages at once also enables a faster throughput than would have been possible by a pick and place system working on its own.

From the beginning the customer was impressed by the technology used and the way the DTS can be customised individually to meet this demanding requirement.

“I was looking for a system that would work very precisely as the vials are made of from glass and can break easily. The handling had to work both rapidly and precisely together with the robots plus the feeding system. This is necessary to guarantee high efficiency and avoid problems such as machine breakdowns. The design works at high speed, is mechanically robust and very accurate.”

Recommended for you

Contact us

Tel Sales Enquiries +44 (0)1884 257000 General Enquiries +44 (0)1884 243400

Email [email protected]

Address

HepcoMotion Head Office

Lower Moor Business Park

Tiverton Way

Tiverton

Devon, EX16 6TG

Contact Form