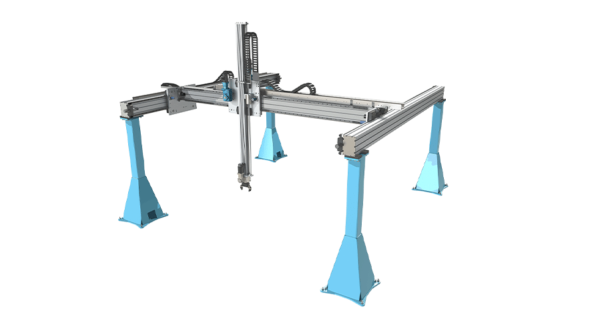

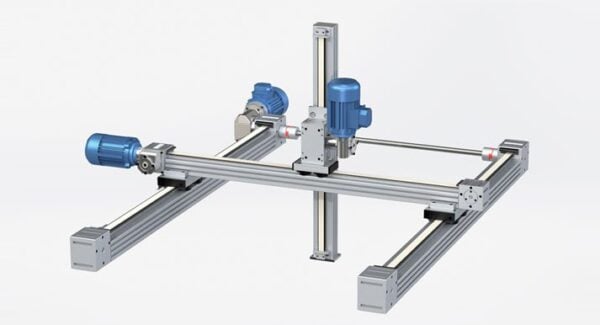

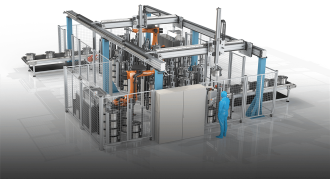

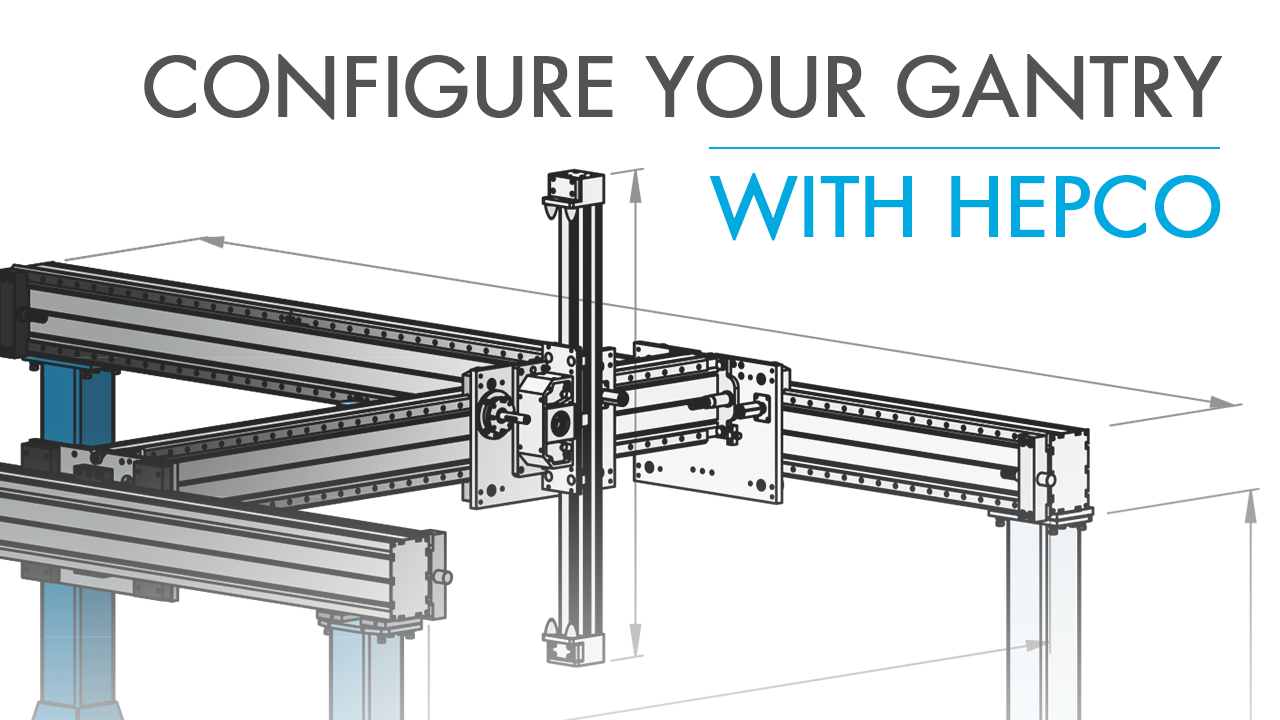

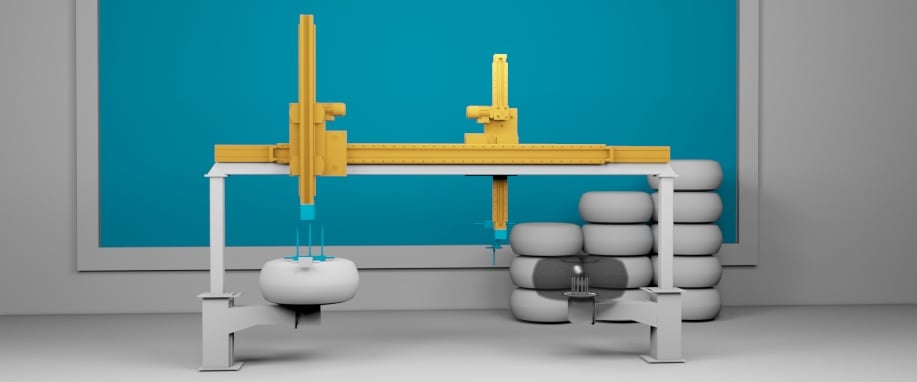

HepcoMotion’s in house design team is experienced in providing designers with complete linear motion solutions. If you require a gantry system, XYZ system or X Y System, Hepco has the solution for you.

Gantry FAQs

XY and XYZ gantries are systems used for precise and automated positioning of tools, sensors, or other devices in various applications such as manufacturing, 3D printing, laser cutting, and inspection. These gantries are named based on the number of axes they operate along. Read more

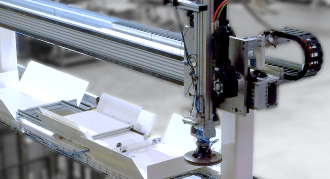

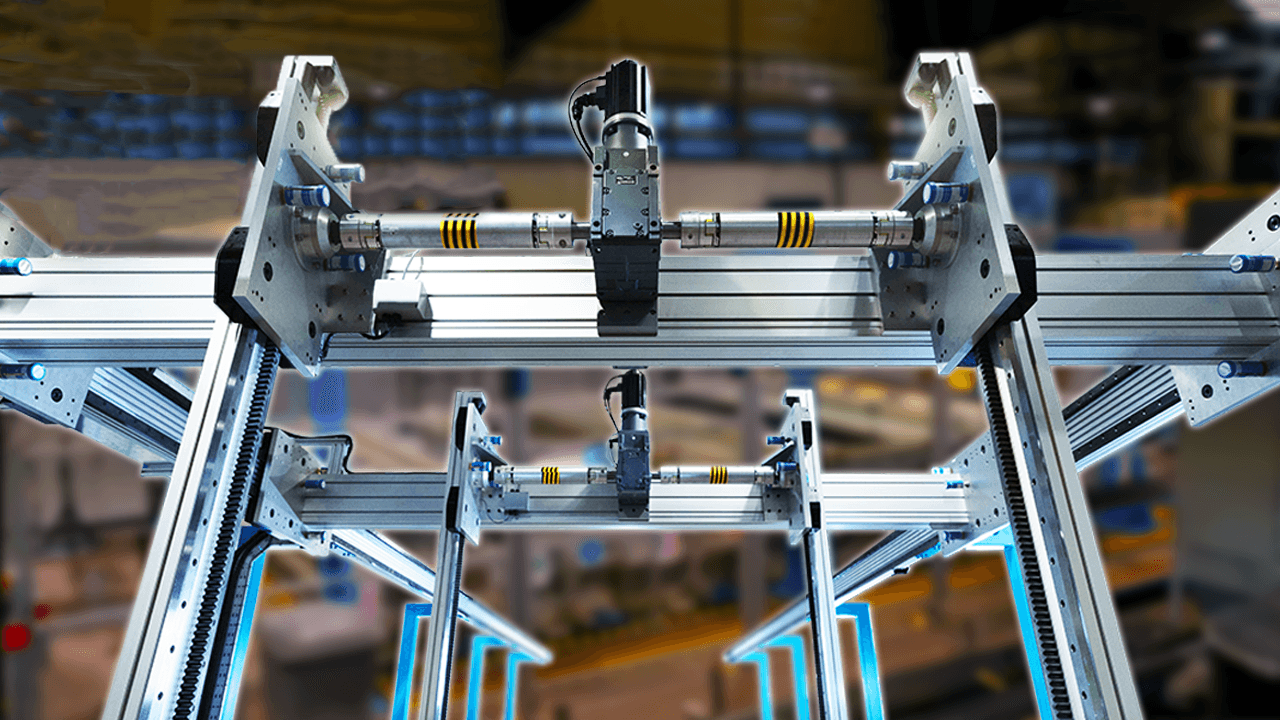

XY gantries provide two-directional movement, which means they move horizontally (along the X-axis) and vertically (along the Y-axis). XY gantries are widely used in applications that require precise two-dimensional movements, such as pick-and-place, material handling, and inspection applications.

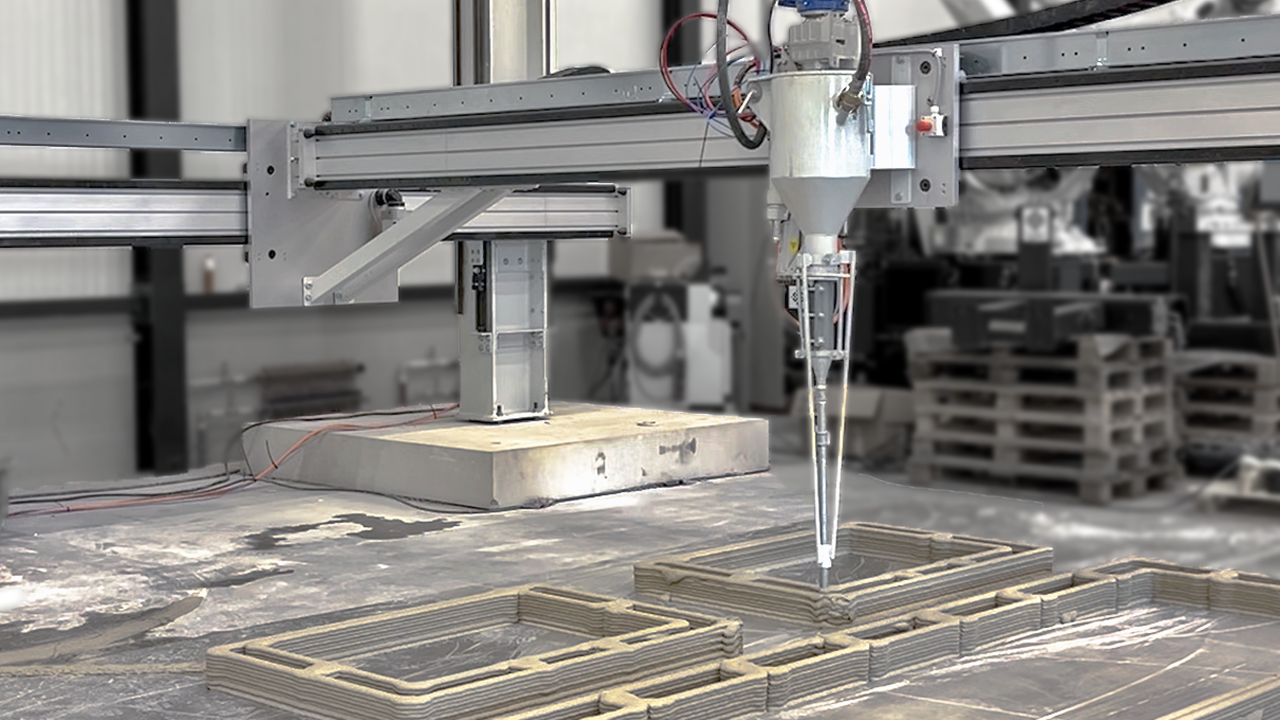

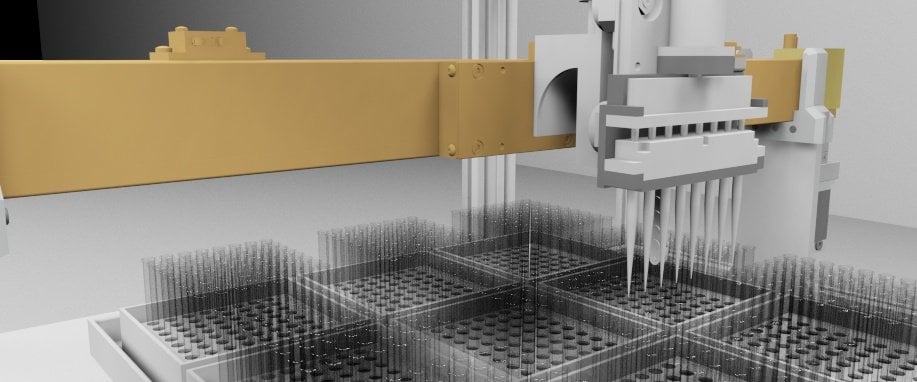

XYZ gantries operate along three axes; X, Y, and Z. Like XY gantries, they can move horizontally (along the X and Y axes) and vertically (along the Z-axis). XYZ gantries are utilised in applications where three-dimensional movement and positioning are required. For example, in 3D printing, CNC machining, and automated assembly lines, an XYZ gantry allows for precise control of the tool or nozzle in three-dimensional space.

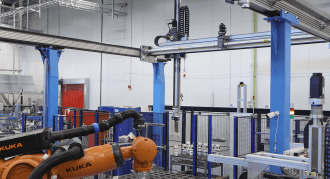

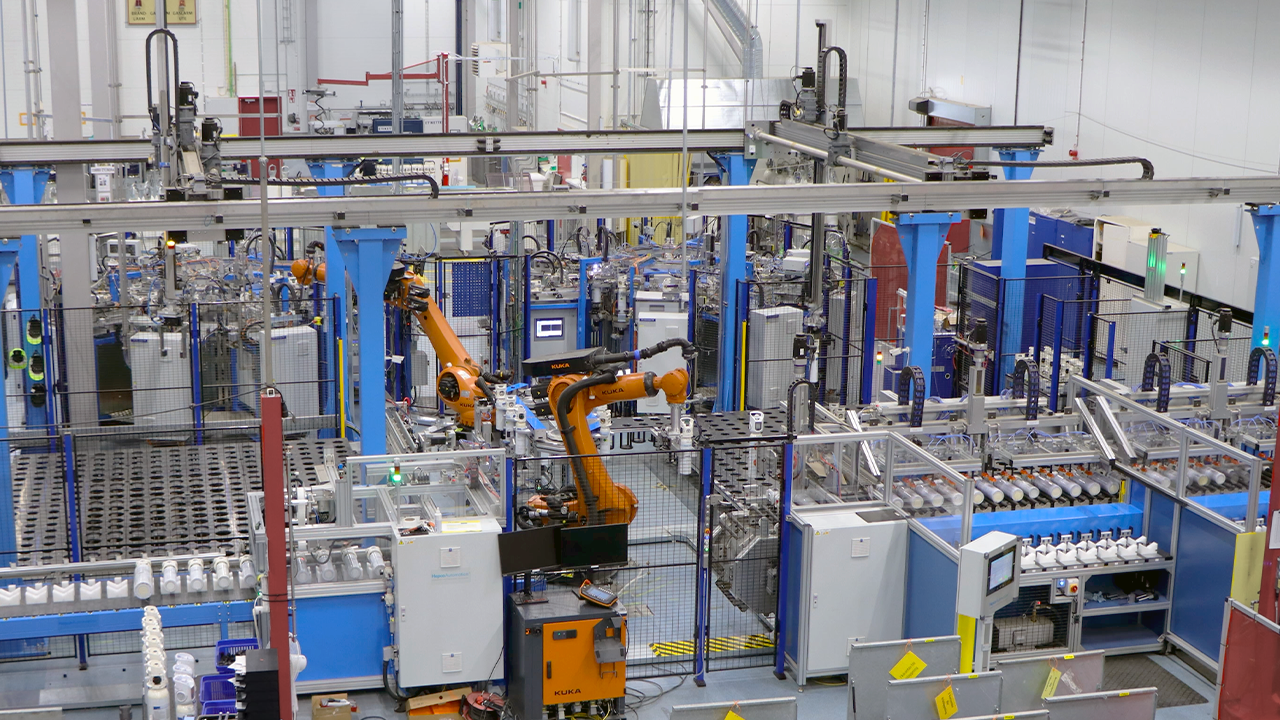

A gantry system and a robot are both types of automated systems used in industrial and manufacturing applications. For many applications, a gantry system can accomplish the same tasks as an industrial robot while incurring less cost and offering greater flexibility. Indeed, where the task involves moving heavy and awkwardly shaped products over a large distance – a gantry system is undoubtedly the better solution. Read more

Gantry systems consist of a fixed structure that operates along linear axes (X, Y, Z) within a predefined workspace. They are ideal for tasks requiring precise linear motion, high payload capacities, and movement over a large distance. Gantry systems are commonly used in applications like CNC machining, 3D printing, and material handling within specific, predefined paths.

Robots have a flexible and articulated structure, offering multiple degrees of freedom and a broader range of motion. Robots excel in tasks that require complex movements and multiple degrees of freedom. While robots can handle a range of payloads, they generally have a lower payload capacity compared to gantry systems.

When choosing a gantry system, it's important to consider several key factors to ensure it meets the specific needs of your application. Firstly, evaluate the payload capacity, ensuring the gantry can handle the weight of your tools or materials without compromising performance. Choose a gantry system that can comfortably support the maximum payload of your application. It's crucial not to overload the system, as it can affect accuracy and longevity. Read more

Environmental factors will also need to be considered. If your application involves a harsh environment (e.g., dust, moisture, extreme temperatures), choose a gantry system designed to withstand these conditions.

Of course, speed will also need to be considered. Different applications demand varying levels of speed and precision. Choose a gantry with appropriate specifications to meet the desired production rates without compromising accuracy.

Our V based technology reduces downtime, increases system life and reduces total cost of ownership.

Discover HowContact us

Tel Sales Enquiries +44 (0)1884 257000 General Enquiries +44 (0)1884 243400

Email [email protected]

Address

HepcoMotion Head Office

Lower Moor Business Park

Tiverton Way

Tiverton

Devon, EX16 6TG

Contact Form