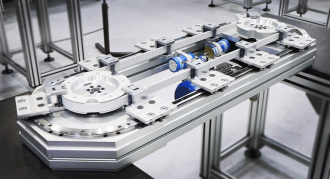

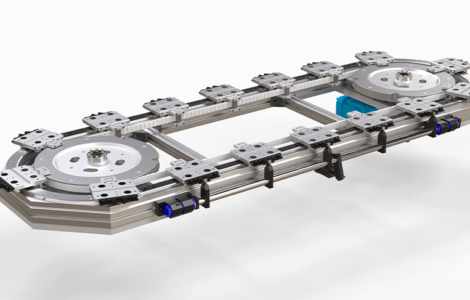

At the heart of your production cell

Move products from station to station in a precise, repeatable and controlled manner.

Work is guided dynamically around closed route cells, controlling the path of components throughout the production process.

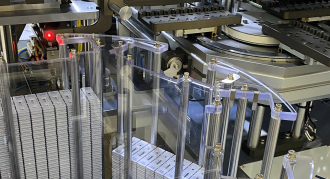

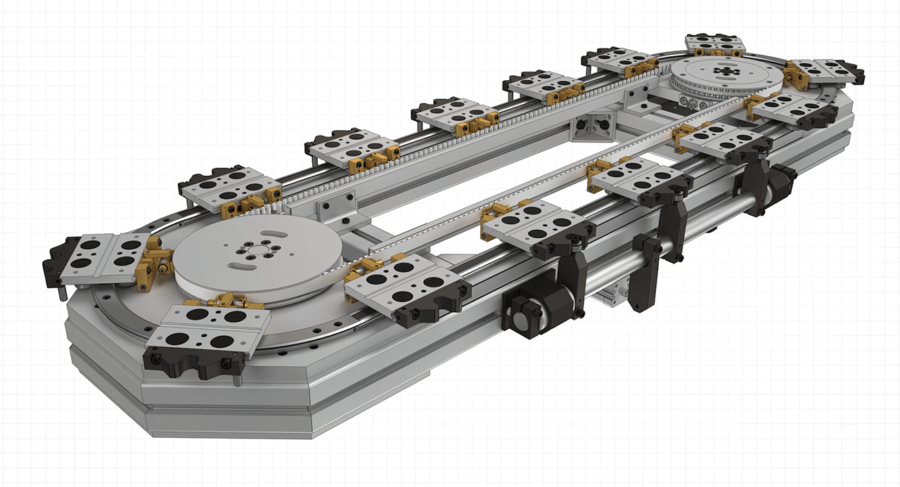

Reduce the Footprint of your machines

DTS systems rationalise linear processes into one continuous closed loop.

The open centre enables equipment to be placed inside and outside of the track system.

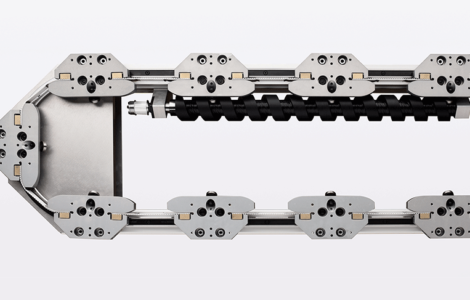

Higher Throughput from your Production

Driven by high-strength steel reinforced timing belts or scroll drives.

High speeds, and accelerations provide greater productivity from your machines.

PRECISE, REPEATABLE POSITIONING DURING PROCESSING

A locking option aligns carriages to within a +/- 0.05 mm repeatable position around the circuit.

Products are then rigidly held in position during processing, enabling consistent quality of throughput.

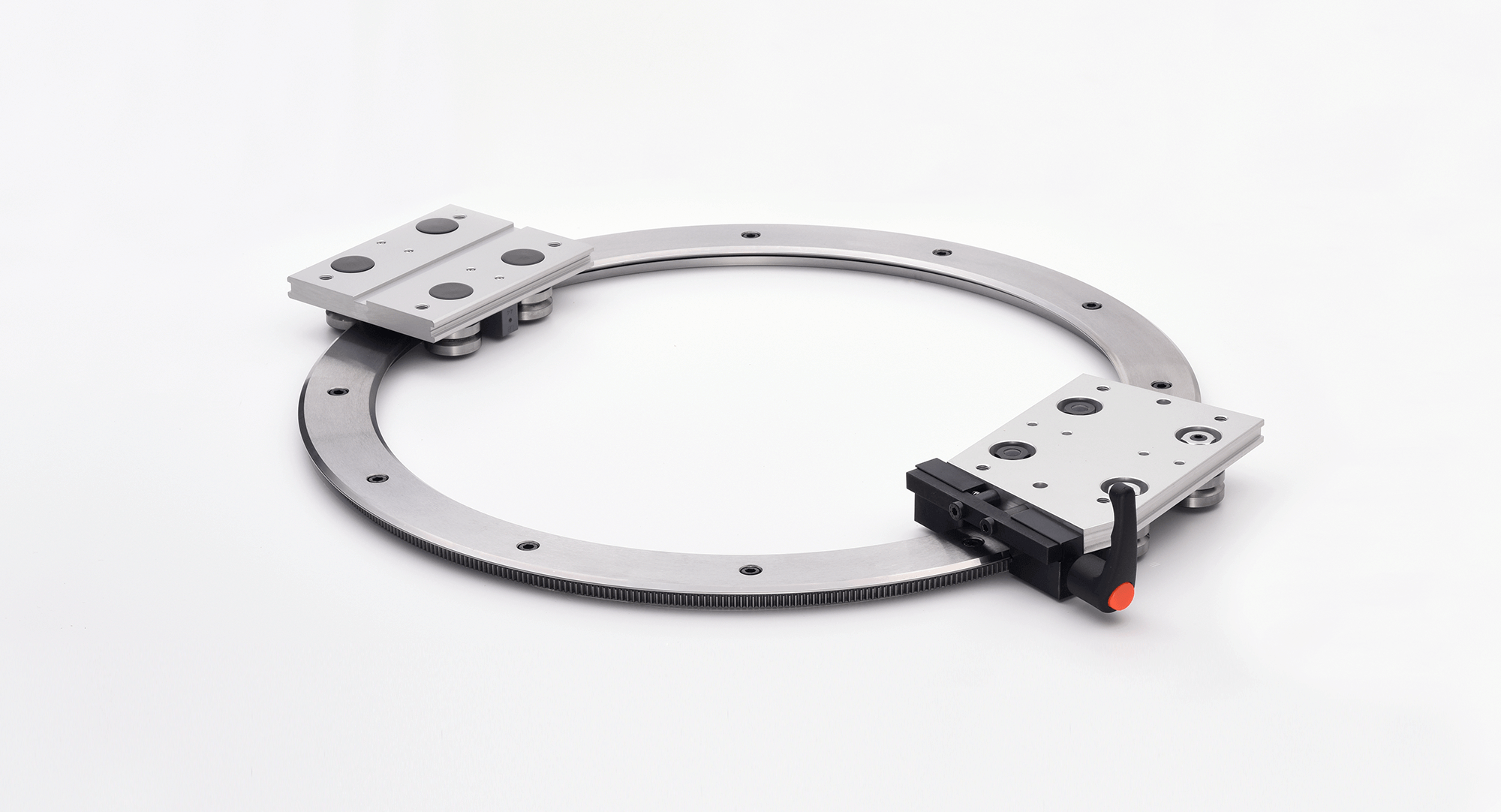

HIGH STRENGTH, LOW-FRICTION GUIDANCE

Hepco’s high strength, hardwearing V-Guide technology, providing smooth and low-friction linear motion.

Ridgely held carriages resist deflection from external forces, guiding components through the production process.

FLEXIBLE AND CUSTOMISABLE

DTS systems are built according to your exact requirements.

Oval, square and rectangular shapes can be designed as standard, and systems work in any orientation.

SELF-CLEANING

Hepco’s V guide system is well suited to harsh environments thanks to its unique wiping action that expels debris.

Dirt is expelled from the bearing during motion, wiping the V guide clean and creating an ideal solution for contaminated environments.

CONTINUOUS AUTOMATED LUBRICATION

Automated lubrication is pumped directly to the contact surfaces of the track system.

This enables extended periods of operation without the need to stop for re-lubrication, reducing downtime and maintenance costs.

The Process Line - Why Driven Track Systems Should Be Its Core

Many modern process lines are less linear than its predecessors. David explains why driven track systems are so well suited for the next generation of process lines.

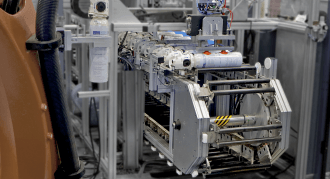

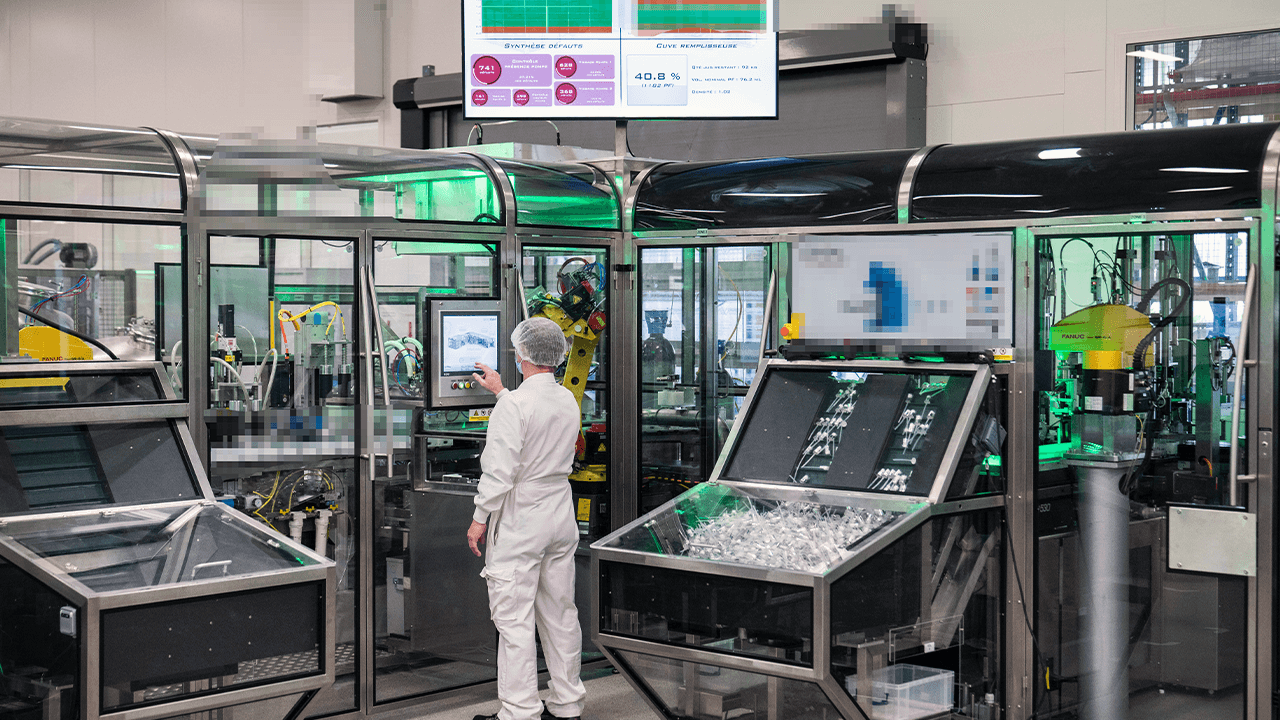

Hepco DTS track systems; the heart of an automated production cell

Automated production cells are now a fundamental part of manufacturing, especially as businesses pursue higher throughput and lower overheads in today’s turbo charged production culture.

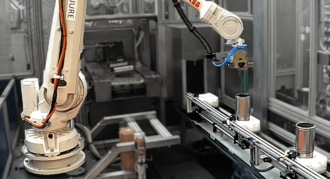

In order to meet high demands for the latest smart phones or laptops, production in the electronics industry must move at breathtaking speeds, still being precise and accurate enough to achieve repeatability and consistent high quality.

DTS belt driven track systems are at the core of modern automation processes, moving products from station to station in an accurate, repeatable, and controlled manner.

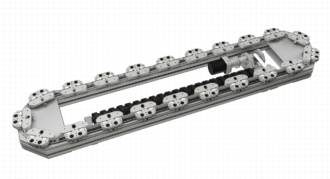

- Available in two track sizes (25mm and 44mm)

- Can operate in a horizontal or vertical position, offering design flexibility

- Can be integrated into a pre-existing system

- A keyed input shaft allows for fitting of motor options or alternative drive solutions

- See the full benefits of DTS systems here

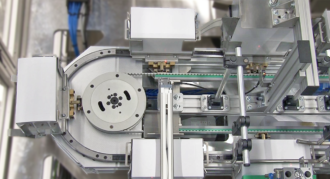

Designed for higher loads requiring speed and accuracy, DTS+ is a ready to fit track and positioning system ideally suited for modern automation processes.

- Easily incorporated into a multi-function machine as a transfer or positioning system

- Wide choice of system sizes with unlimited length

- Available in an oval or rectangular shape

- Corrosion resistant version available

- See the full benefits of DTS systems here

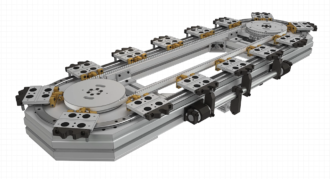

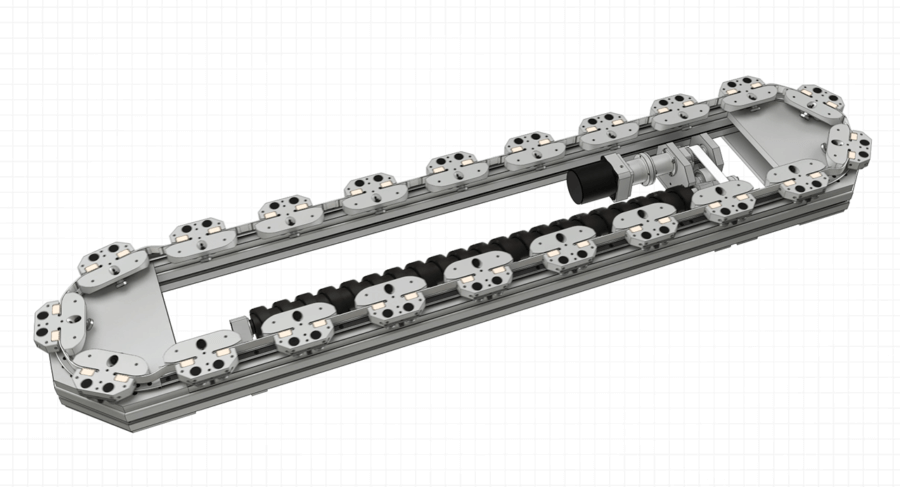

DTS2 is a ready to fit scroll driven track system for high speed and rapid indexing applications requiring smooth movement.

- Available in 2 rail sizes (25 and 44mm)

- Flexibility with carriage length, number and positioning of carriages, subject to minimum technical requirements

- Flexible drive positioning

- Available in stainless steel, with all track, bearing, springs and fasteners in stainless steel

- See the full benefits of DTS systems here

DTS conveyor systems offer high-load capabilities to unique applications.

- High-load precision conveyors

- Compensation for misalignment of parallelism

- Reduces installation time & improves running quality

- Flexible drive positioning

- See the full benefits of DTS systems here

Contact us

Tel Sales Enquiries +44 (0)1884 257000 General Enquiries +44 (0)1884 243400

Email [email protected]

Address

HepcoMotion Head Office

Lower Moor Business Park

Tiverton Way

Tiverton

Devon, EX16 6TG

Contact Form