The design engineer needed to find an effective and compact method to raise, lower, as well as guide a “bucket” full of product from one conveyor line to another.

Solution

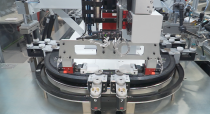

Machine runs continuously, shuttling product from one conveyor to the ones above it. The bucket is raised and lowered through a synchronized toothed belt system attached to wheelplates on either side of the machine.

Scope of Supply

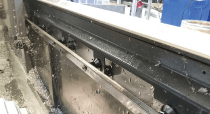

– 8 size W2SSX wheels and bushings.

– 2 M2ATPC-SS x 1550 mm track plates per system.

Result

The designer used pre-mounted track plates, mounted parallel on either side of the machine frame coupled to his own four-wheel carriages. The custom designed carriages were made to do triple duty: to provide a platform for the “V” wheels and an anchor point for the toothed belt while also supporting the rotary actuators which rotate the “bucket”.

Recommended for you

Contact us

Tel Sales Enquiries +44 (0)1884 257000 General Enquiries +44 (0)1884 243400

Email [email protected]

Address

HepcoMotion Head Office

Lower Moor Business Park

Tiverton Way

Tiverton

Devon, EX16 6TG

Contact Form