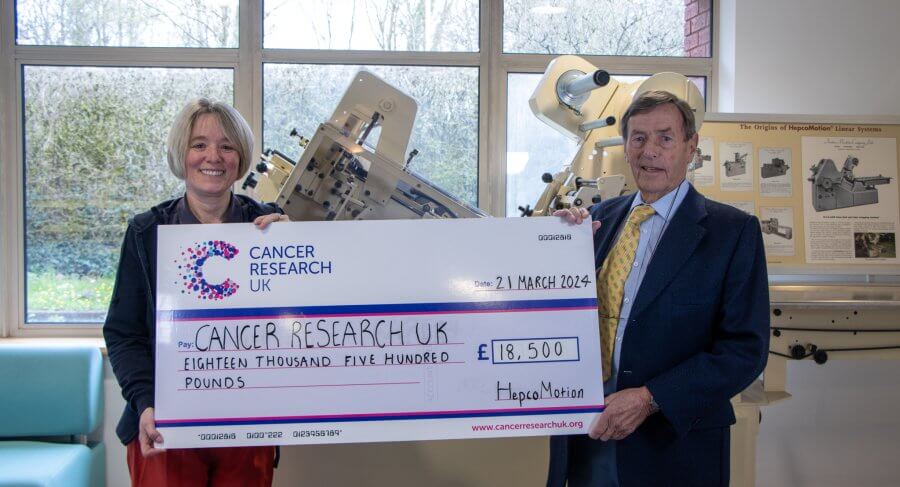

HepcoMotion Raises £18,500 for Cancer Research UK

HepcoMotion recently donated £18,500 to Cancer Research UK (CRUK). HepcoMotion, a world leader in linear motion systems and automation components, has long supported Cancer Research UK. Through ...

Read moreContact us

Tel Sales Enquiries +44 (0)1884 257000 General Enquiries +44 (0)1884 243400

Email [email protected]

Address

HepcoMotion Head Office

Lower Moor Business Park

Tiverton Way

Tiverton

Devon, EX16 6TG

Contact Form